Things You Will Learn

Learn about the different strategies used to design hydraulic systems. This section will help you understand why specific types of hydraulic equipment are used.

HG01 - Industrial CETOP sandwich, manifold or cartridge design strategies

This module discusses some common industrial design techniques including sandwich plate design, platen/manifold mounted design or cartridge design. We cover the history and reasons behind why these techniques have become so widely used along with discussing the types of application where they would be used. Topics covered are:

- Industrial sandwich, manifold or cartridge design strategies

- Background to industrial hydraulic system design

- Line mounted valves

- Sandwich plate mounted valves

- Manifold or platen mounted designs

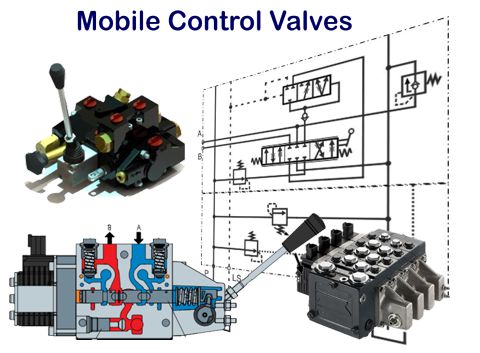

HG02 - Mobile design strategy

This module discusses the mobile, mono-block approach to system design. We cover the history and reasons behind why these techniques have become so widely used along with discussing the types of application where they would be used.

- Basic mobile 6-way valve

- Open centre mobile valve designs

- Closed centre mobile valve designs

- Pressure compensation

- Pre and post-compensated valves

- Load sensing signal

- Reducing and relief valves

- Mono-block end plates

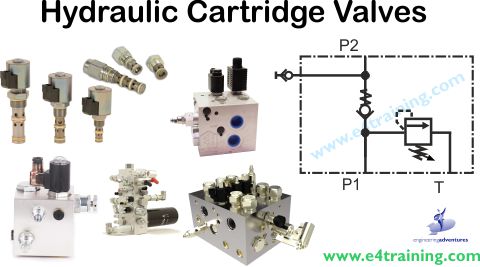

HG03 - Cartridge design strategy

This module discusses the cartridge design approach for hydraulic system design. We cover the advantages and potential issues from using this technique as well as discussing typical application where it may be used.

- What cartridge valves are used for?

- How cartridge valve designs work

- Different types of cartridge valve

- Tips and tricks for maintaining cartridge valve system

- How to specify hydraulic cartridge valves

- Tips and tricks for designing with cartridge valves

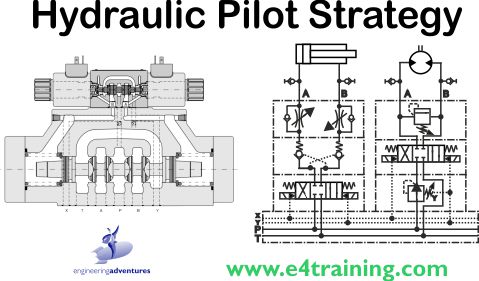

HG04 - Pilot control strategy

This module discusses the use of hydraulic pilot supplies and feeds for controlling hydraulic systems. We cover the background and reasons behind why pilot pressure control is used along with discussing the types of application in which it is used.

- What is a pilot control system?

- How pilot control works

- Different types of pilot pressure control

- Pressure control valve vents

- Pilot pressure drain systems

- Pilot pressure supply systems

- Tips and trips about pilot valves

HG05 - Load Control Strategies

This module discusses the different types of load control system and explains some of the key points to be aware of. Topics covered are:

- Operator Safety

- Load Control Fundamentals

- Counterbalance valve an PO check Features

- Application Advice

- Problems and Solutions.

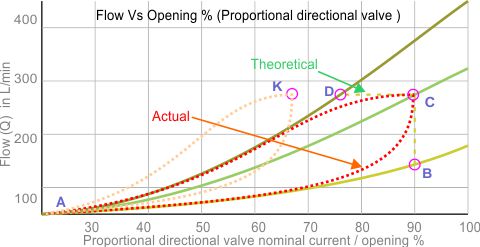

HG06 - Proportional control strategies

This module discusses the different types of proportional control and explains some of the key points to be aware of. Topics covered are:

- Flow control methods

- Load and forces

- Importance of pressure drops

- Pressure compensators

- Machine stiffenss

- Minimum acceleration time

- Open loop quality issues

Proportional Control Strategies

Applies to the following areas

This module applies to both mobile and industrial applications although much of the more comprehensive control features will only be used on industrial applications. Lower cost power units in the industrial sector are very similar to the simpler mobile power units.

Target Audience

People who are responsible for hydraulic equipment in the following ways:

Managing or purchasing hydraulic equipment.

Maintenance Engineers repairing hydraulic equipment.

Hydraulic equipment designs.

Previous knowledge required

Students are expected to be familiar with:

1. The operation of hydraulic fluid power equipment.

2. Understand hydraulic components and where they are used.

3. Able to read hydraulic circuit and their symbols.