Things You Will Learn

Learn about the basic principles that form the foundation of all hydraulic equipment. This section explains some of the key factors that should always be considered.

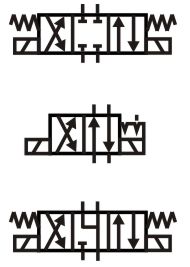

HP03 - Understand Hydraulic Symbols

This module provides an introduction to the basic symbols for hydraulic pumps, valves, and actuators. This is followed by a detailed review of all major hydraulic component symbols, explaining their features and also how the components work.

- Explanation of the symbols in a simple hydraulic circuit.

- Access to a full review of all major hydraulic symbols.

Start Hydraulic Symbol Training

- Basic symbol introduction

- Check or shut off valves

- Directional control valve symbols

- Pressure control valve symbols

- Hydraulic flow control valve symbols

- Servo and proportional valve symbols

- Slip-in logic cartridge valve symbols

- Hydraulic pump symbols

- Ancillary hydraulic equipment symbols

- Hydraulic measuring equipment symbols

- Hydraulic actuator symbols

- Valve actuation mechanism symbols

- Hydraulic course lesson plans

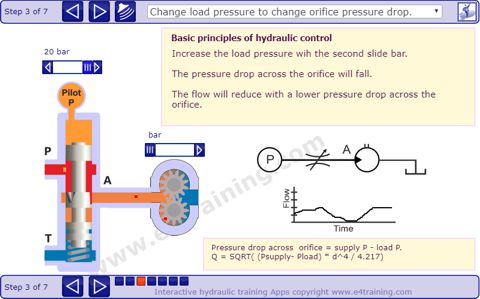

HP01 - Fundamental Valve Principles

This module explains basic principles of hydraulic control. Understanding these parameters will help you analyse the performance of every hydraulic component.

- Fluid PRESSURE creates FORCE on a PISTON creates MOVEMENT against a SPRING.

- PRESSURE DROP across and ORIFICE creates FLOW proportional to the orifice SIZE.

- LOAD PRESSURE changes, affect the CONTROL PRESSURE.

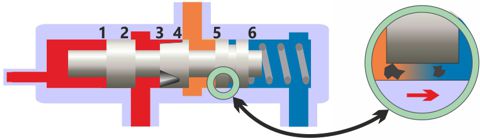

- LEAKAGE results from small CLEARANCES between the SPOOLS and BORES.

- Dynamic SEALS reduce leakage but cause HYSTERESIS.

- Restricting VOLUME changes is used to control TIMINGS.

Start Fundamentals Training Video Instruction Interactive Experiment

HP04 - Fluid Cleanliness is Vital in Every System

This module highlights the importance of minimising fluid contamination and discusses ways the fluid cleanliness levels can be controlled.

- What fluid contamination is

- The importance of minimising fluid contamination

- Sources of fluid contamination - risk factors.

- Methods of controlling or reducing fluid contamination - preventative measures

Start Fluid Cleanliness Training Video Instruction Interactive Experiment

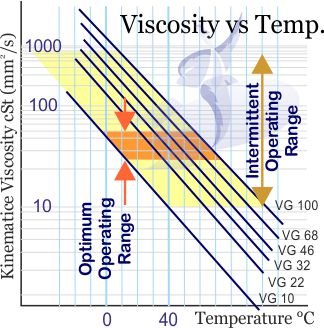

HP05 - Understanding Hydraulic Fluids

This module looks at the key characteristics of hydraulic fluid including the different types available and how to keep them in good condition.

- Functions of hydraulic fluid

- Hydraulic fluid characteristics

- Different types of hydraulic fluid

- How to avoid damaging hydraulic fluid

HP02 - Identify Hydraulic Design Priorities

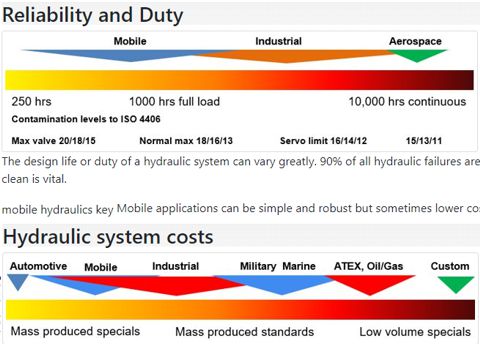

All hydraulic machines are not the same, this module explains why. We look at the different performance priorities for a range of equipment.

- The relationship between hydraulic, pneumatic, or electrical drives.

- The differences between hydraulic systems on different machines.

- The different priorities engineers apply when design hydraulic systems.

- Common strategies used by hydraulic engineers to achieve their design priorities.

HP06 - Noise in Hydraulic Systems

This module will help you understand what causes noise to be generated and then radiated from hydraulic systems.

- Noise sources. The causes of fluid-borne noise and how to reduce them.

- Noise transmission. The generation of pressure ripple and how to reduce transmission.

- Noise radiation. How pressure pulsations create airborne noise and how to reduce noise radiation.

Start Fundamentals Training Video Instruction Interactive Experiment

Relevant Sectors

This module will identify and explain some of the most important hydraulic design features that are common in every system.

Applies to all fluid power sectors e.g. Industrial, mobile, machine tools, specialist machines etc.

Contamination control is more critical for higher performance servo and proportional equipment but applies to all areas of hydraulics.

Hydraulic fluid is the blood in every system and a vital component for maintaining a health equipment.

Target Audience

People responsible for hydraulic equipment by:

- Operating a range of hydraulic equipment.

- Maintaining a range of hydraulic equipment.

- Purchasing hydraulic equipment.

- Managing equipment that contains hydraulic valves.

- Design engineers should already understand these concepts but a refresh will make sure.

- Safety awareness is essential for EVERYONE working on or close to fluid power systems. Additional precautions will be required if you are carrying out maintenance activities of some kind.

Previous knowledge required

Students are expected to be familiar with:

What and where hydraulic fluid power is used for e.g. types of machines and industries.

Basic hydraulic circuit components and operation e.g. pumps, valves, and actuators.

Further Reading

More safety information can be found at the HSE website