Things You Will Learn

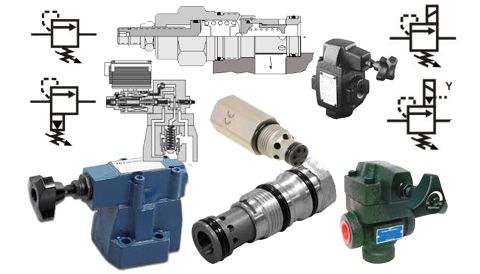

Learn about the range of hydraulic valves available and how they work. Understand where and why they are used and how to get the best performance from them.

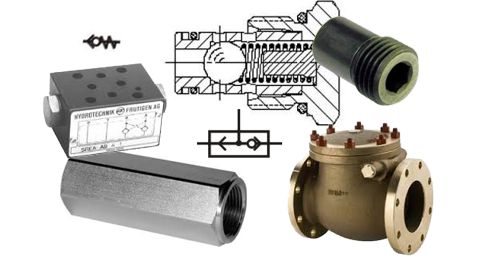

HV01/2 - Hydraulic check valve design and application

This module covers the basic design, usage, and types of hydraulic check valve. We discuss typical applications and issues with using hydraulic check valves.

- What check valves are used for

- How hydraulic check valves work

- Different types of hydraulic check valves

Start Hydraulic Check Valve Basics Training

Video Instruction Interactive Experiment

- Tips for operating and maintaining check valves

- Design features and operating characteristics

- How to specify hydraulic check valves

- Design tips, techniques, and potential issues

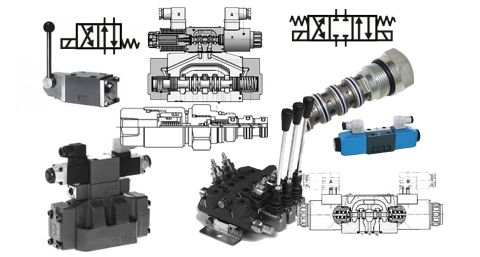

HV03/4 - Hydraulic directional valve design and application

This module covers the basic design, usage, and types of hydraulic directional valve. We discuss typical applications and issues with using hydraulic directional valves.

- What directional valves are used for

- How hydraulic directional valves work

- Different types of hydraulic directional valves

Start Hydraulic Directional Valve Basics Training

Video Instruction Interactive Experiment

- Tips for operating and maintaining directional valves

- Design features and operating characteristics

- How to specify hydraulic directional valves

- Design tips, techniques, and potential issues

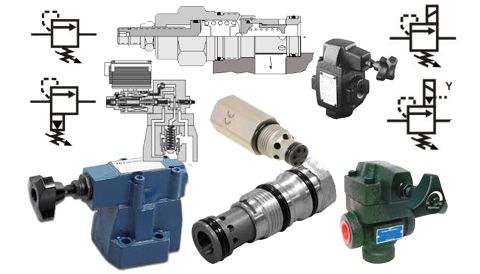

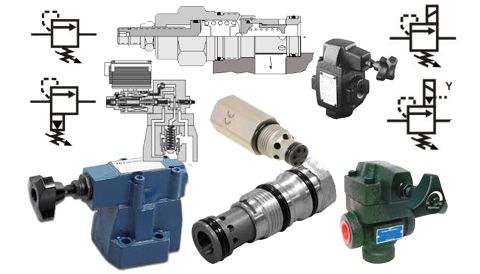

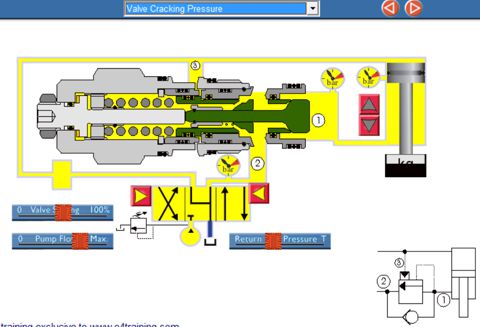

HV05/6 - Pressure relief valve design and application

This module covers the basic design, usage, and types of hydraulic pressure relief valve. We discuss typical applications and issues with using hydraulic relief valves.

- What pressure relief valves are used for?

- How hydraulic relief valves work

- Different types of hydraulic pressure relief valves

Start Hydraulic Pressure Relief Valve Basics Training

Video Instruction Interactive Experiment

- Tips for operating and maintaining relief valves

- Design features and operating characteristics

- How to specify hydraulic relief valves

- Design tips, techniques, and potential issues

HV07/8 - Hydraulic flow control valve design and application

This module covers the basic design, usage, and types of hydraulic flow control valve. We discuss typical applications and issues with using hydraulic flow valves.

- What flow valves are used for

- How hydraulic flow control valves work

- Different types of hydraulic flow control valves

Start Hydraulic Flow Valve Basics Training

Video Instruction Interactive Experiment

- Tips for operating and maintaining flow control valves

- Design features and operating characteristics

- How to specify hydraulic flow control valves

- Design tips, techniques, and potential issues

HV09/10 - Pressure reducing valve design and application

This module covers the basic design, usage, and types of hydraulic pressure reducing valve. We discuss typical applications and issues with using pressure reducing valves.

- What reducing valves are used for?

- How hydraulic reducing valves work

- Different types of pressure reducing valves

Start Hydraulic Reducing Valve Training Basics Training

Video Instruction Interactive Experiment

- Tips for operating and maintaining reducing valves

- Design features and operating characteristics

- How to specify hydraulic reducing valves

- Design tips, techniques, and potential issues

HV11/12 - Sequence valve design and application

This module covers the basic design, usage, and types of hydraulic sequence valve. We discuss typical applications and issues with using pressure sequence valves.

- What reducing valves are used for?

- How hydraulic sequence valves work

- Different types of sequence valves

Start Hydraulic Sequence Valve Training Basics Training

Video Instruction Interactive Experiment

- Tips for operating and maintaining sequence valves

- Design features and operating characteristics

- How to specify hydraulic sequence valves

- Design tips, techniques, and potential issues

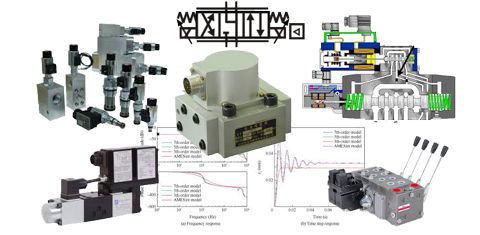

HV13/14 - Hydraulic proportional valve design and application

This module covers the basic design, usage, and types of hydraulic proportional valve. We discuss typical applications and issues with using hydraulic proportional valves.

- What proportional valves are used for?

- How hydraulic proportional valves work

- Different types of hydraulic proportional valves

Start Hydraulic Proportional Valve Basics Training

Video Instruction Interactive Experiment

- Tips for operating and maintaining proportional valves

- Design features and operating characteristics

- How to specify hydraulic proportional valves

- Design tips, techniques, and potential issues

HV15/16 - Hydraulic counterbalance valve design and application

This module covers the basic design, usage, and types of hydraulic counterbalance valve. We discuss typical applications and issues with using hydraulic counterbalance valves.

- What counterbalance valves are used for?

- How hydraulic counterbalance valves work

- Different types of hydraulic counterbalance valves

Start Hydraulic Counterbalance Valve Basics Training

Video Instruction Interactive Experiment

- Tips for operating and maintaining counterbalance valves

- Design features and operating characteristics

- How to specify hydraulic counterbalance valves

- Design tips, techniques, and potential issues

Relevant Sectors

This module is not market specific but will clarify the difference between all types of hydraulic valves and their applications.

Target Audience

People who are responsible for hydraulic equipment in the following ways:

1. Operating hydraulic equipment.

2. Managing or purchasing hydraulic equipment.

3. Maintenance and Design Engineers

Previous Knowledge Required

Students are expected to be familiar with:

1. Where hydraulic fluid power is used e.g. types of machines and industries.

2. Basic hydraulic circuit layout.

3. Able to recognise hydraulic component and their symbols.

Further Reading

TBC