What you will learn in this section

Things You Will Learn

Learn about the range of hydraulic pumps and motors available and how they work. Understand where and why they are used and how to get the best performance from them.

HD01 - Summary of the Different Hydraulic Pump Types

This module introduces people to the range of hydraulic pump types and discusses some of the reasons why they are used in particular applications.

- Recognising the different types of hydraulic pumps.

- Basic hydraulic pump design principles.

- Understand what the different types of hydraulic pumps are used for.

HD02 - Hydraulic Gerotor Pumps and Motors

This module provides a brief introduction to the use of gerotor pumps in the fluid power industry, even though this relatively infrequent.

- What gerotor pumps are used for?

- How gerotor pumps work

- Different types of gerotor pumps

HD03/4 - Internal and External Gear Pumps and Motors

This module looks at the basic operation and application of both internal an external gear pumps before reviewing more detailed installation, application, and maintenance advice.

- What gear pumps are used for?

- How internal and external gear pumps work

- Different types of hydraulic gear pumps

- Tips for operating and maintaining

- Typical operating characteristic

- How to specify

- Design tips, techniques, and potential issues

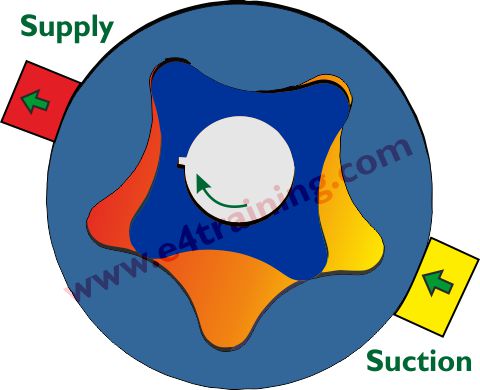

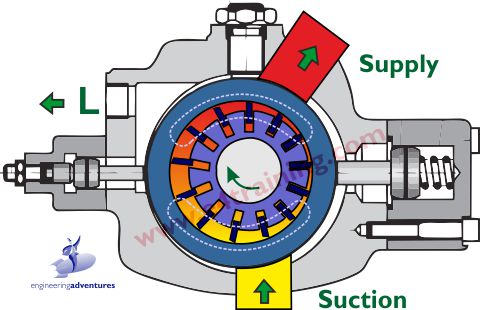

HD05/6 - Hydraulic Vane Pumps and Motors

This module looks at the basic operation and application of both fixed and variable displacement vane pumps before reviewing more detailed installation, application, and maintenance advice.

- What hydraulic vane pumps are used for?

- How vane pumps work

- Different types of vane pumps

- Tips for operating and maintaining vane pumps

- Typical operating characteristic of vane pumps

- How to specify vane pumps

- Design tips, techniques, and potential issues

HD07/8 - Axial Piston Pumps and Motors, Fixed and Variable

This module looks at the basic operation and application of both fixed and variable displacement piston pumps before reviewing more detailed installation, application, and maintenance advice.

- What hydraulic axial piston pumps are used for?

- How hydraulic axial piston pumps work

- Different types of axial piston pumps

- Tips for operating and maintaining piston pumps

- Typical operating characteristic piston pumps

- How to specify piston pumps

- Design tips, techniques, and potential issue

HD09 - Radial Piston Pumps

This module looks at the basic operation and application of both fixed and variable displacement piston pumps before reviewing more detailed installation, application, and maintenance advice.

- What hydraulic radial piston pumps are used for?

- How hydraulic radial piston pumps work

- Different types of radial piston pumps

HD11 - Low Speed High Torque LSHT Motors

This module looks at the basic operation and application of both fixed and variable displacement low speed high torque LSHT piston motors before reviewing more detailed installation, application, and maintenance advice.

- What hydraulic LSHT motors are used for?

- How hydraulic LSHT motors pumps work

- Different types of LSHT motors

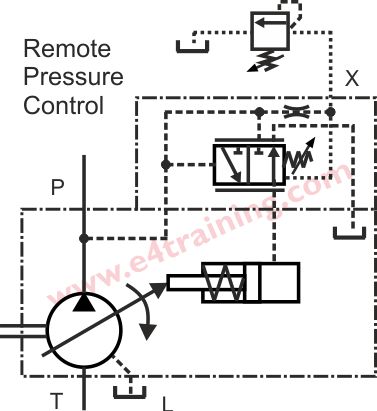

HD12 - Variable Displacement Pump Controllers

This module reviews the main types of control used on variable displacement pumps. We discuss their design, operation and uses for:

- Two position switching pump control

- Pressure compensated pump control

- Remote pressure pump control

- Pump flow controller

- Electronic pump controller

- Pump power control valves

- Load sensing pump control

Relevant Sectors

This module is not market specific and will clarify the difference between all types of hydraulic pumps and their applications.

Target Audience

People who are responsible for hydraulic equipment in the following ways:

1. Operating hydraulic systems.

2. Managing or purchasing hydraulic equipment.

3. Maintenance and Design Engineers

Previous Knowledge Required

Students are expected to be familiar with:

1. Where hydraulic fluid power is used e.g. types of machines and industries.

2. Basic hydraulic circuit layout.

3. Able to recognise hydraulic component and their symbols.

Further Reading

TBA