Understand where and why reducing valves are used. The different types available and how they work.

Self-study lesson plans and training record download page.

1-2 What pressure reducing valves do and where they are used

Pressure reducing valves are used to provide a stable pressure to part of a circuit that requires a lower pressure than the pump's supply. This may be required because the actuator or loads are not designed to take the full system pressure or simply that they don't need the full pressure. In reality, most designers try to avoid using pressure reducing valves as they don't want to include additional valves and they can normally adjust the cylinder sizes to achieve the correct load for the supply pressure.

A common use for reducing valves is to create a lower, more stable pressure for pilot circuits or valves. Often these pilot valves or secondary circuits require lower pressures to that of the main stage circuit and by reducing the pressure, the pilot valves can be shielded from any spikes or peaks that may be present in the main loaded circuit lines.

Pressure reducing valves are also used to control other valves. For example, varying the pressure on the end of a control valve's spool will move it against a spring. Using a reducing valve to achieve this is generally preferable to a pressure relief valve as the quality of control and dynamics are better and the loss of fluid is significantly reduced. This approach is common in mobile, mono-block control valves.

1-2 How pressure reducing valves work

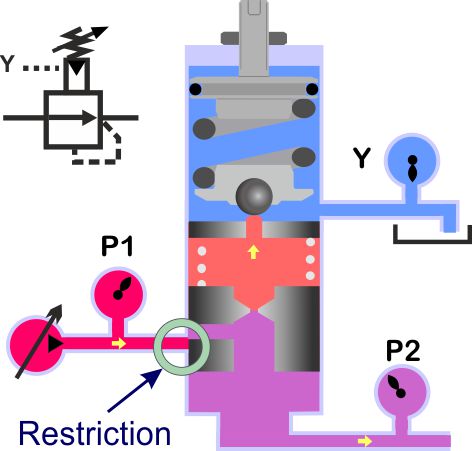

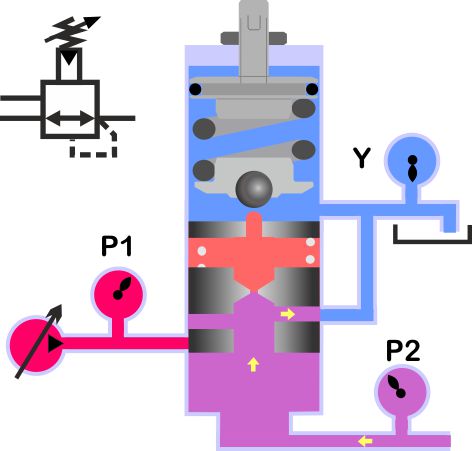

Pressure reducing valves don't create pressure, they simply close the flow path to stop the flow going through them when the downstream load pressure reaches the reducing valve's setting. Reducing valves sense the pressure downstream of the valve, unlike relief valves which sense the pressure upstream of the valve. Looking at the pilot sensing line on the hydraulic symbol is how you identify whether it is a relief or reducing valve.

Some reducing valves have a relief function as well as the reducing function. This means that if the load pressure increases above the reducing valve's setting, it will relieve the pressure from the load. While all reducing valves need a third line to sense a reference, atmospheric pressure, on some valves this may just be a pilot vent line to relieve the pressure, while on others it may be larger to take some flow.

To reduce the pressure, reducing valves simply throttle and restrict the flow rate going through them. This restriction creates a pressure loss, generates heat, and can waste a large amount of energy. Although this may still waste less energy than using relief valves.

When the flow is restricted the pressure upstream of (before) the valve is likely to rise to full pump supply pressure. Clearly, this has to work in conjunction with the other valves in the circuit so that there is somewhere else for the excess flow to go, or have a variable displacement pump so that the flow is not be produced.

Look at the different reducing valve symbols here.

2-3 Different types of pressure reducing valve

Reducing valves may also be known as a pressure regulating valve or reducing/relieving valve.

Because of the need to regulate the flow rather than simply opening and closing, all pressure reducing valves utilise spool elements rather than poppets. For this reason, they usually exhibit some leakage, unless the spool is fitted with a seal, which would cause a higher hysteresis.

Pressure reducing valves come in direct and pilot-operated versions. The direct operated valves are available in lower flow versions only but because they have only one, single-stage, they tend to have faster response times than the larger, two-stage, pilot operated valves. This faster response does, however, make them more unstable.

Pilot-operated reducing valves have a pilot valve and a main stage valve. This allows them to control higher flows but they will also exhibit larger, constant loss leakage flows.

Sometimes manufacturers have the same type of valve available with different dynamic response rates. They may not advertise these in their brochures but can be supplied if you experience instability issues during commissioning etc.

As with other valves they are available in cartridge, platen-mounted, or line-mounted options.

Advanced reducing valve training

Learn more about reducing valves in our 'Professional Training Section'. Understand their design features, performance limits, and how to specify reducing valves.