Understand where and why proportional valves are used. The different types available and how they work.

Self-study lesson plans and training record download page.

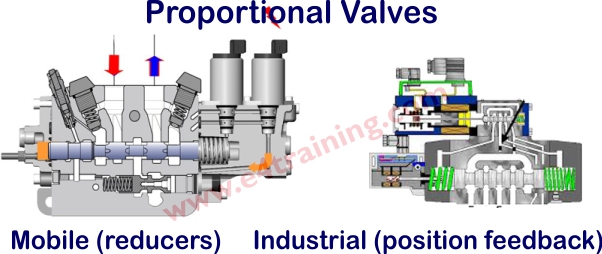

1-2 What proportional valves do and where they are used

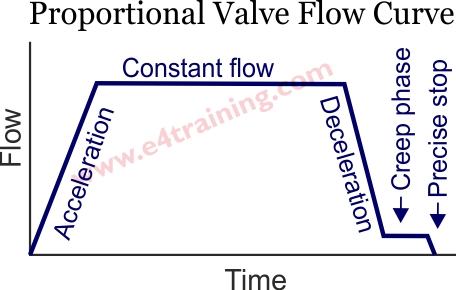

Directional valves are either open or shut, they offer no control of flow rate and their operation can be very harsh, as they move instantly from fully open to fully closed. Proportional valves, on the other hand, are used to control the acceleration and/or speed of a load, by providing smooth control of valve opening and closing speeds as well as controlling the flow of fluid that passes through the valve when it is open.

In mobile excavators proportional control valves are widely used to move the arms and buckets smoothly. With mobile equipment, the operator moves a handle to gradually start to move the implements and then have control over the speed at which they move.

In mobile excavators proportional control valves are widely used to move the arms and buckets smoothly. With mobile equipment, the operator moves a handle to gradually start to move the implements and then have control over the speed at which they move.

In industrial applications proportional control valves are used when different speeds are required or when actuators need to stop at a specific position. They are also used to gradually speed up and slow down actuators so that they don't judder or start harshly.

In industrial applications proportional control valves are used when different speeds are required or when actuators need to stop at a specific position. They are also used to gradually speed up and slow down actuators so that they don't judder or start harshly.

High performance proportional and servo valves are used to provide greater accuracy or a high-precision of speed, pressure, or positional control is required, often with electrical closed-loop control rather than open-loop control.

1-2 How proportional valves work

Hydraulic proportional control valves work in a similar way to directional valves except they do not switch from fully shut to fully open. Instead, they gradually open a restricted flow orifice area. The size of the orifice opening is proportional to the amount the spool moves, either controlled by an electrical solenoid or a hand lever. In this image, you can see a directional spool switching (on top) and a proportional spool gradually opening (below). The proportional spool has a triangular notch that gradually opens a flow control orifice as it moves.

Flow is proportional to the amount that the valve orifice opens although the actual flow rate will also vary as the load or supply pressure changes. The shape and quality of the notch is also very important. Using a triangulated notch instead of a circular radius will provide a more linear flow vs opening characteristic.

It's useful to think of hydraulic control valves as a braking technology, rather than a driving one. They can be compared to a car's brakes rather than its engine. Valves, like brakes, are much smaller and control the vehicle's load by throttling or decelerating, rather than accelerating the vehicle, like an engine does.

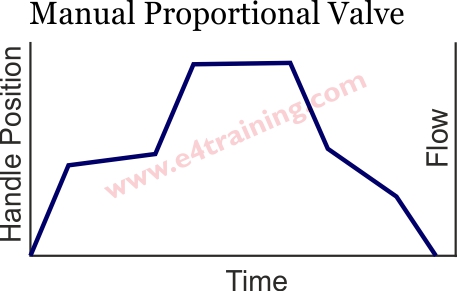

Manually operated proportional valves

Manually operated proportional valves

With a manually operated proportional valve you simply control the position of the spool with the position of the operating handle. Moving the spool increases the size of the notch opening and therefore reduces the size of the orifice restriction.

With a manually operated proportional valve you simply control the position of the spool with the position of the operating handle. Moving the spool increases the size of the notch opening and therefore reduces the size of the orifice restriction.

Mobile control blocks often use proportional pilot pressure control valves on the ends of the spools. These allows either electrical or hydraulic, remote pilot pressure control handles, to be located away from the proportional flow control valves.

Mobile control blocks often use proportional pilot pressure control valves on the ends of the spools. These allows either electrical or hydraulic, remote pilot pressure control handles, to be located away from the proportional flow control valves.

Industrial proportional valves

Industrial proportional valves

Industrial proportional control valves more commonly use direct electrical actuation with PWM (pulse width modulated) power control to the solenoids. The electrical signal controls the force the coil exerts against the spring on the far end of the spool, and therefore the spool position and orifice size.

Industrial proportional control valves more commonly use direct electrical actuation with PWM (pulse width modulated) power control to the solenoids. The electrical signal controls the force the coil exerts against the spring on the far end of the spool, and therefore the spool position and orifice size.

Accuracy is always a key issue with proportional control. In this graph, the cylinder position after the main deceleration phase would vary after each cycle. The creep phase is used to slowly bring the cylinder to a final limit switch before quickly decelerating to a more consistent stopping position.

2-3 Types of proportional valves

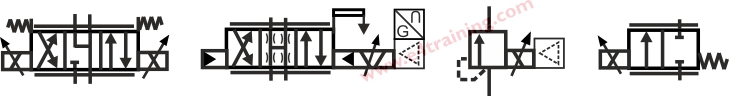

There are proportional versions of most types of hydraulic valve e.g. ones regulate gradually rather than switching between set levels. These include directional, pressure, and flow control valves, both poppet and spool types.

Servo valves were often referred to as Moog valves but are essentially high performance proportional valves that operate using an overhead torque motor with a mechanical feedback arm linked to a flapper nozzle, rather than solenoids. Modern electronics means that proportional valves can now achieve a similar level of performance.

See our symbols sections for more details.

Quality, cost, and performance can be very different between similar looking proportional control valves. The following is a list of some of the key areas to be aware of when specifying, using, or maintaining a servo or proportional valve.

Operating mechanism and control card hardware or software. Control notch type and accuracy. Spool leakage rates. Overlap or underlap percentage, does the spool work inside a machined sleeve.

Direct or indirect spool activation along with the nature of pilot valve fluid supply and drain line pressures.

The system design, including loads, pressure drops, and pipe dimensions will have a significant effect on the performance. Spools may cut with different opening ratios on the A and B sides to provide more consistent raising (less restriction) and lowering (more restriction) speeds.

Are the valves controlling the load's acceleration and deceleration or just the speed of the movement?

Are the valves controlled in open or closed loop and does the valve utilise internal closed loop control of spool position.

What are the system natural frequencies e.g. 3Hz to 1000Hz and what are the valve natural frequencies e.g. 20Hz to 400Hz. Do they compare adequately?

Cylinder positional accuracy required e.g. 0.1 to 0.001mm

Pressure and flow control accuracies required and what happens during start-up, shutdown, or loss of power.

Servo valve torque motor and flapper valve or high performance proportional valves with internal or external electronics.

As you can see there is a huge range of operating, quality and performance factors to consider so any work on these valve must be undertaken by a suitably qualified person.

Advanced proportional control valve training

Learn more about proportional control valves in our 'Professional Training Section'. Understand their design features, performance limits, and how to specify proportional and servo valves.