Things You Will Learn

Learn about the equipment and procedures required for safe operation and maintenace. This section will help you understand which specific products, designs, and procedures are used to ensure long, reliable and safe operation of hydraulic equipment.

HS02 - Opereate, Start-up and Shut-down Procedures

Learn how to operate equipment safely with typical start-up and shut-down procedures.

- Typical start-down procedures

- Typical operating procedure

- Typical shut-down procedures

- Planned and preventative maintenance

- Reporting and recording facilities

HS03 - Safety Awareness and Risk Assessment

Understand your duties under HSAWA Act 1974. We look at the meaning of hazards and risk and discuss some of the requirements and best practice for keeping yourself and your colleagues safe.

- Learn how to identify hazards and risks

- Understand how to produce a risk assessment.

- Understand the importance of reporting and communicating actions to be taken.

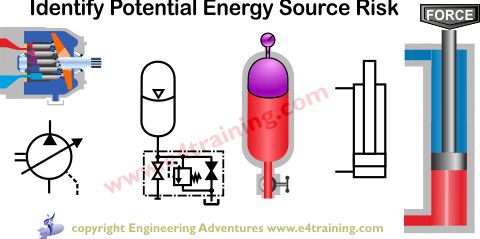

HS04 - Potential Fluid Power Risks

This module will review the potential risks from fluid power systems. We look at the potential dangers associated with fluid power systems including:

- Stored energy

- Equipment that has not been pressure tested

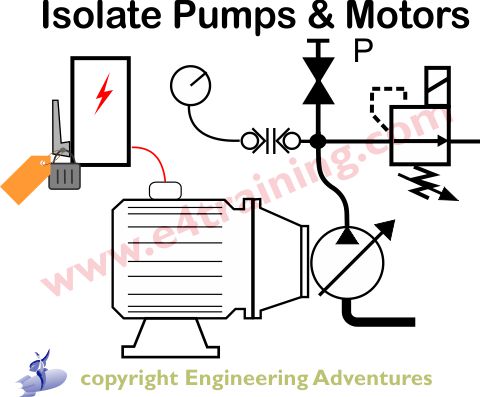

- Safe start up and isolation procedures

- Fluid leakage risks

- Hydraulic hose dates, conditions and installations

- Specific local safety issues

- Heat sources risks

- Fluid injection injury potential and action plan

Additional general safety considerations:

Noise levels

Electrical hazards

- Working in a confined space

- Working at height

- Manual handling, lifting of heavy or awkward objects

HM01 - Design Features for Improved Maintenance

This module will review a range of design features and discuss how and why they are used to improve equipment life and maintainability. Issues discussed include:

- Contamination Control

- Hydraulic Reservoir Facilities

- Air or Water in Fluid

- Hydraulic Filters Maintenance Facilities

- Fluid quality and working life

- Hydraulic Coolers Design for Maintenance Considerations

- Motors Design Maintenance Considerations

- Hydraulic Pumps Maintenance Considerations

- Hydraulic Actuators Maintenance Considerations

- Directional Control Valve Maintenance Considerations

- Proportional and Servo Valve Maintenance Considerations

- Pressure Control Valve Maintenance Considerations

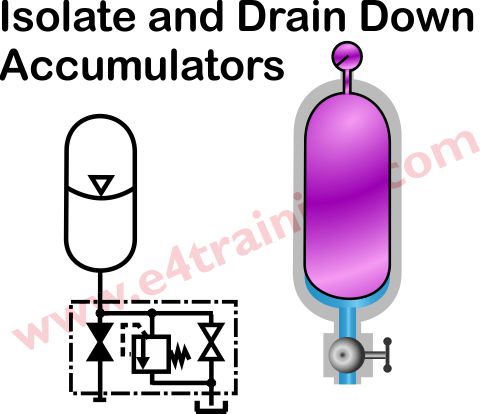

- Accumulators Maintenance Considerations

- Hydraulic hoses Maintenance Considerations

- General System Maintenance Facility Considerations

- Power Unit Design Examples 1-3

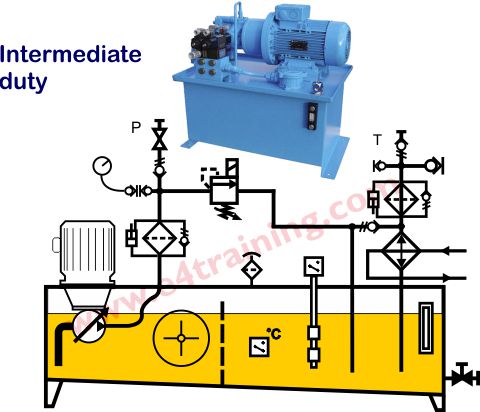

HM02 - Power Unit Maintenance Examples

This module will review the features of a number of power unit examples and discuss how and why they affect the equipment life and maintainability. Example include:

- Simple Power Unit Design Example 1

- Intermediate Power Unit Design Example 2

- Heavy Duty Power Unit Design Example 3

HM03 - Preventative and Planned Maintenance

This module will review typical planned and preventative maintenance considerations and procedures. Issues discussed include:

- Preventative Maintenance

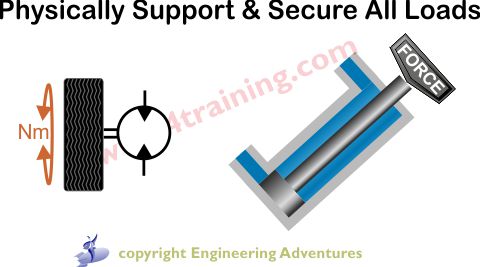

- Preparation for Planned Maintenance

- Planned Hydraulic Maintenance Tasks

- Pumps and Motors Maintenance Tasks

- Hydraulic Filter and Air Breather Maintenance Tasks

- Hydraulic Fluid Maintenance Tasks

- Cylinders and Rotary Actuator Maintenance Tasks

- Spool Valve Maintenance Tasks

- Poppet Valve Maintenance Tasks

- Benchmarking Fluid Power Maintenance

- Unplanned Repairs and Fault Finding

- Maintenance Procedures

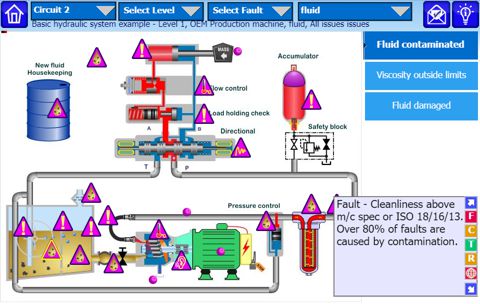

HM04 - Hydraulic Troubleshooting Tool

This troubleshooting application will help your identify, diagnose and repair a wide range of common breakdown faults in hydraulic systems. Topics discussed include:

- Hydraulic troubleshooting steps

- Troubleshooting tips and tricks

- Hydraulic troubleshooting video

- Hydraulic fault diagnostic software