Self-study lesson plans and training record download page.

What gerotor pumps and motors are used for

Gerotor pumps are simple and robust but not hugely efficient or high performing. This limits their use as pumps too low to medium pressure feed or lubrication systems particularly designed into custom products in the automotive sector. As motors, particularly with roller designs, they are widely used in smaller wheel or belt drive systems etc.

How gerotor and geroler pumps and motors work

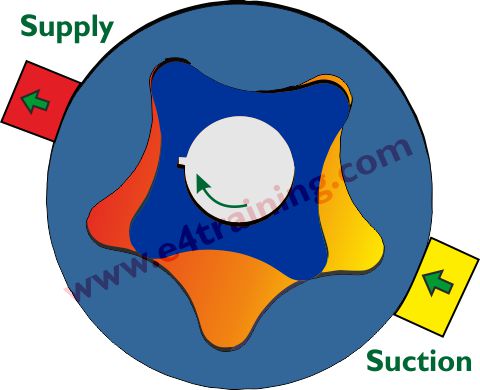

As the inner rotor turns relative to the out rotor they open an increasing volume over the suction port. Into which fluid is pushed by the atmospheric pressure. As the inner rotor continues to rotate the suction port is closed and the supply port opens. At this point the trapped volume starts to decrease, pushing the fluid out of the supply port.

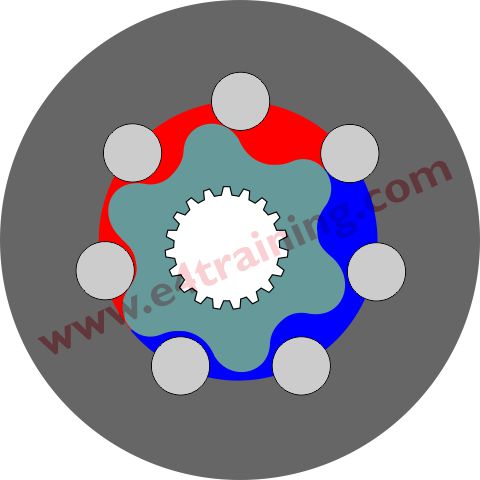

In some designs, the rotors are allowed to float against each other. With this approach, clearances are kept to a minimum but mechanical efficiency is reduced. Rotating the impellers on bearings improves the mechanical efficiencies but relies on the very accurate manufacture of the impellers to maintain the end tip clearances. Therefore volumetric efficiency may be reduced. There will always be a small clearance on the side of the rotors which will also reduce overall efficiencies.

Different types of gerotor pumps and motors

The two main types are the one piece rotor and roller rotor designs. The second providing tighter tolerances and therefore higher performance and longer life.

Gerotor pumps can operate in one or both directions.

Tips for operating and maintaining

Always keep the fluid clean as the shaft bearings are lubricated by the same fluid that is being pumped.

Check the manufacturer datasheet carefully for the maximum side loads that can be applied to the drive shaft. Wheel motors often have large in-build wheel bearings whereas pumps might not be able to take any side load at all.