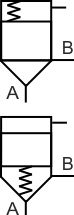

Slip-in cartridge, logic valve symbols

Slip-in cartridge or logic valves are generally used in high flow circuits when other CETOP of mobile slice valves cannot be used. They are different from the smaller, cartridge valve designs which tend to be more compact, lower-cost versions of traditional valves.

The top symbol shows a pressure control or directional control, poppet design, cartridge valve with a 1:1 area ratio, and normally closed type.

The bottom symbol shows a normally open type, pressure control or directional control, poppet design, cartridge valve with a 1:1 area ratio.

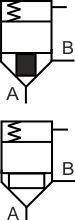

Area ratios and response times

Poppets with different area ratios can be used to provide different levels of performance and response. Because slip-in cartridges tend to be relatively large the flow within the internal volumes can be damped with screw-in orifice plugs to control the operating speeds.

The top symbol shows a directional control, poppet valve cartridge with a throttle nose (shown by black) area ratio =< 0.7

The bottom symbol is a directional control cartridge poppet valve with an area ratio > 0.7.

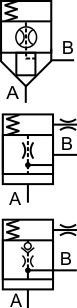

Flow or pressure control versatility

Slip-in cartridges can be configured to provide a wide range of performance characteristics. Applying different pilot feeds and control orifice allows the basic poppet insert to perform a range of different tasks.

The top symbol shows a directional control non-return valve function with a replaceable orifice restrictor fitting in the internal pilot supply flow.

The middle symbol shows a normally closed pressure relief valve with a spool design type.

The lower symbol shows a normally open, spool-type, pressure reducing valve with an integrated orifice and non-return valve.

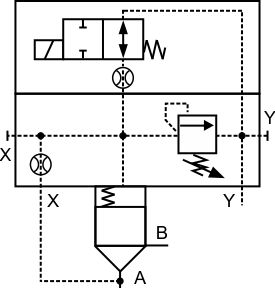

Control covers provide flexible functionality

Small, standard, hydraulic valves fitted into the control covers that fit on top of the slip-in cartridge valves can provide a very flexible way of creating a lot of different, high flow, valve functions.

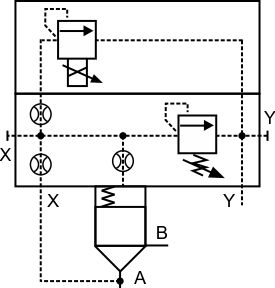

This symbol shows how a small directional and relief valve can be added to create a high flow, normally open, solenoid-operated, unloader, and pressure limiting relief valve.

Control circuits within each valve assembly

Designing logic valve circuits is not as easy as it looks. There are so many different basic poppet types and they tend to be sensitive to having the optimum damping orifice size (pilot flows) to smooth out the variations from the poppet nose flow forces. But once mastered the range of control and performance options that are available is huge.

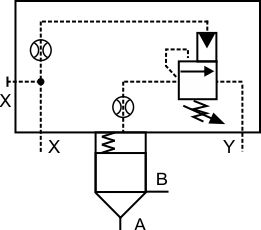

This symbol shows a proportional pressure control valve with manually adjustable maximum pressure limiting.

Describe the function of this valve

What functions does the valve shown in this symbol provide.

What functions does the valve shown in this symbol provide.