With thanks to Ian Harris - Product Manager, Houghton UK, for contributing information included in this module.

Self-study lesson plans and training record download page.

Lubricates moving surfaces

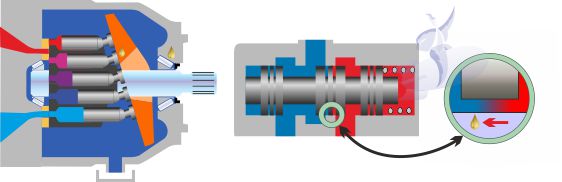

Hydraulic fluid lubricates and protects every component inside the hydraulic circuit. Maintaining good fluid quality is vital for maintaining the necessary fluid film thicknesses required for hydrostatic bearing and spool clearances. Hydraulic systems can take such high loads and keep working for such long periods because none of the moving parts ever touch. There should always be a thin film of fluid between them but if this breaks then contact will be made, dirt generated and many components will fail.

As well as lubricating the pump bearings and moving spools the fluid flow will also clear away any contaminants that are generated between moving parts and return the dirt particles back to the filters in the reservoir.

How hydraulic oils operate

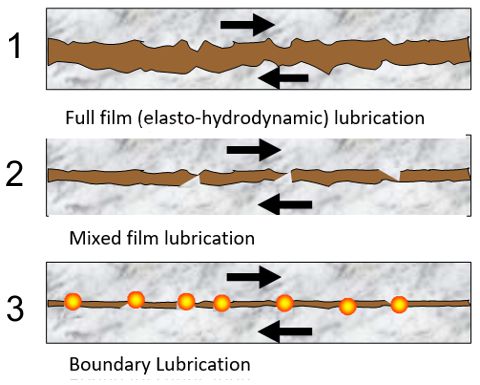

Hydraulic oils operate in a wide variety of equipment, applications and environments from fixed installations to mobile machines, from small to large systems, indoor and outdoor. Their functions may include power transmission, cooling, and protection against corrosion, but their key task is to prevent wear in what are generally described as three levels of lubrication regime:

1. Low loads and pressures. Metal surfaces are separated by an oil film. Needs the CORRECT VISCOSITY but no additives.

2. Medium loads and pressures. Some contact between sliding metal surfaces. Needs ANTIWEAR additives.

3. Heavy loads and high pressures. Very high level of metal to metal contact. Needs EXTREME PRESSURE (EP) additives.

There are two essential parameters that must be defined in order to select the correct lubricant for an application, namely VISCOSITY and ADDITIVE PACKAGE.

Fluid Power transmission

Hydraulic power is transferred around the system via the fluid. The energy can be used anywhere in the circuit with very few energy losses as it passes through the pipework. Hydraulic fluid is generally considered incompressible so that no energy is stored within the fluid itself and a volume of flow in one section of the circuit must be the same as the volume moved in another part of the circuit. However, when considering highly dynamic systems the modulus of elasticity of the oil is important and can lead to oscillations or instabilities.

Corrosion protection

Machined surfaces can rust very quickly when left in contact with the air. Hydraulic fluid protects the ferrous components from corrosion while they are submerged and even for short periods when they are exposed to the air, such as when cylinder rods extend or during short maintenance periods.

For storage of components or during longer periods of maintenance it is important to ensure components are adequately protected. This is normally achieved by sealing them, with oil, in airtight bags and may include special preservative oils that include vapour phase inhibitors (VPIs) to further protect components from the moisture in the air.

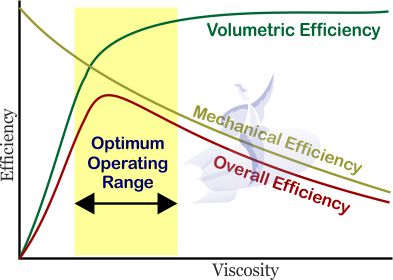

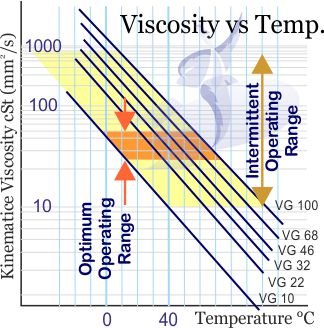

Kinematic viscosity key fluid characteristic

Kinematic viscosity, measured is in centistokes (cSt), is one of the most important characteristics when deciding which fluid should be used. The performance and efficiency of every hydraulic component will depend on the fluid viscosity. Pumps are particularly sensitive to thick fluids affecting their inlet pressure on cold mornings and will be damaged by too thin fluid if they run too hot. Hydraulic filter and valves can be subject to unacceptable pressure drops if the fluid viscosities move outside their specified range. All equipment will have been designed to work within a specific fluid viscosity range.

Dynamic and kinematic viscosity

Dynamic viscosity is derived from the speed at which certain mass falls through a tube of fluid. It is measured in centipoise (cP). This defines the fluid's resistance to flow when an external force is applied. Kinematic Viscosity, measured in centistokes (cSt) is calculated from the dynamic viscosity divided by the fluid density.

Kinematic viscosity if the figure that is usually described as a fluid's viscosity.

Fluid viscosity vs temperature

Fluid temperature will significantly change its viscosity. For maximum performance and reliability, it is vital that the fluid temperature remains within the system design, operating limits. These should include an optimum working range of probably around 40-55 C and then a maximum and minimum limit for intermittent operation, say for start-up and very hot days etc., of perhaps 5 C to 80 C. The actual values are likely to have been derived from the pump manufacturers' viscosity limits while considering the fluid required and environments conditions the equipment will be working under.

Having the right viscosity is crucial in all types of application. A measure of the thickness of the oil, viscosity can be expressed in a variety of units, but most standards today are based on centistoke units at 40 C. The International Standard ISO3448 defines specific viscosities in these terms, e.g. ISO VG22, 32, 46, 68, 100, 150, 220, 320, and so on, with an allowance of +/- 10%.

Most OEM's specify suitable viscosity grades for their hardware and typical values might be ISO VG10 for a machine tool spindle, VG32 or 46 for most hydraulic systems, VG68 or 100 for warm running hydraulic systems.

Operating temperature is crucial. Oils get thinner as they get warmer and thicker when cold. Viscosity Index, or VI, is a number that indicates the viscosity stability of an oil vs temperature and is calculated from measurements at 40 C and 100 C. Larger numbers mean less variation. A standard hydraulic oil will typically have a VI of around 100. By using suitable oils and additives, this can be boosted to 150 or more, giving 'multigrade' oils, useful for external environments.

Fluid additive package

For full film lubrication, oils without additives may be used, but the minimum suggested additive treatment is with Rust and Oxidation inhibitors, which offset the issues caused by moisture ingress and by localised heating of the oils as they pass around the system. A variety of additive chemistry can be used including phenolic compounds, etc.

Mixed film lubrication, most commonly the case in hydraulic applications, calls for Antiwear additives, which attach to, and create low friction films on the metal surfaces (asperities). Additives are mainly based on Zinc or Sulphur-Phosphorus chemistry.

Boundary lubrication, e.g. in some gearboxes and slide-ways requires Extreme Pressure (EP) additives. These react with metals at the hot spots to form low friction compounds. Again, Sulphur-Phosphorus chemistry is predominant.

Understand which hydraulic fluid to use

HLP - mineral oil based fluids

Mineral oil based hydraulic fluids are probably the most widely used fluid within the hydraulics industry. They are comparably low cost, widely available, and provide good all-round performance. Like other fluids, they are often available in naturally and or synthetic versions.

Biodegradable hydraulic fluids

Biodegradable hydraulic fluids are becoming more widely used in particular they are often required in forestry equipment, where any loss of fluid would cause some damage to the environment. They are typically produced from vegetable oils, rather than petroleum, and there are a number of different alternatives to choose from. System life and/or performance are likely to be compromised although this is a rapidly improving sector and there can be significant advantages from using them.

Fire resistant fluids

Fire resistant fluids are available as HFC - Water Glycols, HFA - Water in Oil Emulsions, and HFD - Anhydrous synthetic fluids. Different system designs and seal types need to be specified for each fluid and it is unlikely that fluids can be changed on individual systems. Please be aware that most can still ignite but are far more resistant to fire than mineral oil-based fluids.

Always read the fluid datasheets carefully before working with a specialist fluid. Some create toxic gases in enclosed spaces and others can be damaging to the skin. One example exhibiting both of these issues is Skydrol, which, is a common phosphate ester, aircraft fluid.

All fluids must be prevented from dispersing into the environment.

Never mix hydraulic fluid types

Avoid mixing different types of hydraulic fluids and always top-up with exactly the same fluid formulation. If a different fluid type is required then consult with the fluid supplier and they will probably advise a suitable fluid to flush the system with first.

Hydraulic fluids should only need changing when a chemical analysis shows that their properties are damaged or contaminated. It's preferable to keep the same fluid in good condition rather than switching to new fluid with the inherent risk of adding new contaminants as well. When changing to new fluid it's virtually impossible to remove every drop of the old fluid. In this case, it is generally accepted that up to 5% of residue fluid should not be likely to cause an issue.

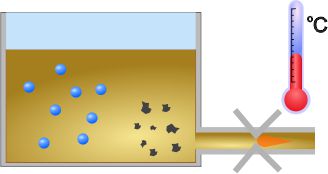

How fluid damage effects service life

Poor fluid condition is likely to result in a drop in the performance and efficiency of the hydraulic components. This will lead to an ever-increasing amount of contaminant being generated and that will lead to a reduced service life and increase in breakdowns and maintenance costs.

Keeping the fluid in good condition is one of the best ways to keep running costs as low as possible.

Check out this advice for maintaining fire resistant fluids.

Factors that can cause fluid deterioration

Hydraulic fluid can be damaged by a number of factors:

Oxidation is caused when oxygen combines with the chemicals in the fluids to create unwanted residues that can damage component surfaces. Oxidation typically occurs at the reservoir surface and increases significantly as temperatures rise.

Water can often enter the fluid from leaking coolers or condensation on the reservoir walls. Small quantities may evaporate naturally but if the fluid appears milky then action should be taken as water will reduce lubricity and lead to surface damage.

Air bubbles or foaming may occur from badly designed reservoirs or leaking pump inlet connections. After maintenance, cylinder lines should be bleed of and control lines purged by flushing. Increasing the pressure above 70 bar should draw the air into solution, from where it can be flushed back and released in the reservoir.

High local pressure drops, typical in many control systems, can create very high local temperatures which then result in damage to the fluid. High fluid shear stresses, in these areas, can directly damage and reduce the viscosity of some fluids.

Contamination, from any source, many not specifically damage the fluid but does render it as enemy number 1 in every hydraulic system.

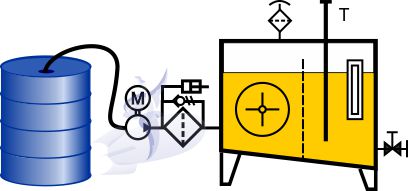

Storage, transfer and maintenance tips

It is vital that the environment around every hydraulic system is maintained as clean as possible. Never leave fluid in open containers and always pump new fluid into the system via the appropriate filter.

Always use lint-free cloths to clean surfaces and never leave internal component surfaces open to the atmosphere for long periods. Bleed and the flush all sections of hydraulic pipe where components have been removed and replaced. This will purge the air clean contaminant that will have entered the fluid in the area of the repair. Protect all spare parts in sealed bags, in a suitable storage facility and with the appropriate preservative fluids where necessary.

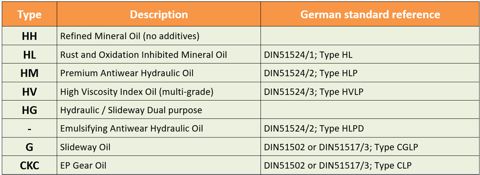

How the various fluid types are defined

The International Standard ISO 6743 is one recognised general classification system based on composition and additive types. ISO 6743 applies to lubricants, industrial oils and related products. Another popular classification based on German standards is DIN, especially DIN 51524 for hydraulic fluids.

When choosing the correct lubricant, the equipment manufacturers' recommendations must always be the prime source. Viscosity and additive type must BOTH be considered. A point to note is that many HM-type hydraulic fluids use a Zinc-based antiwear package. This is generally suitable for most systems, however there are variants of the HM-types which use a Zinc-free (ashless) additive package which is more suitable for systems prone to water contamination or run at higher than `average' temperatures. The Zinc-free packages also have a better compatibility with certain bearing types ie; Silver alloy and Phosphor-Bronze pump parts. Choosing the wrong additive package could be a costly mistake!

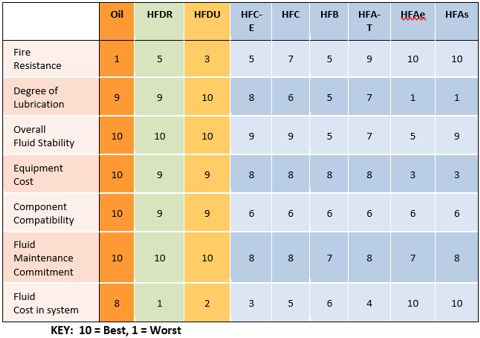

Fire resistant hydraulic fluid types

Fire resistant hydraulic fluids are also classified into their various types by the International Standard ISO6743-4. The types differ in chemical and physical nature and together they create a portfolio offering a wide range of fire resistance, lubrication performance, cost and other key properties. The main types are shown below:

WATER-FREE FLUIDS:

ISO - L - HFDR - Phosphorus esters - without water

ISO - L - HFDS - Chlorinated hydrocarbons - without water

ISO - L - HFDT - HFDR / HFDS mixtures

ISO - L - HFDU - Anhydrous liquids, more resistant than HFDR, HFDS or HFDT

These fluids rely on their inherent chemical nature for fire resistance, and there are two main sub types:

HFDU fluids are based on esters, either synthesised (sometimes called polyol esters), or direct from certain vegetable oils. They have higher flash and fire points than conventional oils but require additives to modify their spray droplet size to achieve better fire resistance. These grades are an easy substitution for replacing mineral hydraulic oils as their material compatibilities are very similar to oil, so minimal changes are need to system fittings and fixtures.

HFDR fluids are also esters, but contain phosphorous atoms, hence are 'phosphate esters.' Even higher flash and fire points, with no need for droplet size modifiers. HFDR fluids operate in systems specifically designed for this chemistry. Disposal can be more costly than other fluids.

Other HFD types also exist based on chlorinated hydrocarbons, but are very rarely encountered.

WATER-BASED FLUIDS:

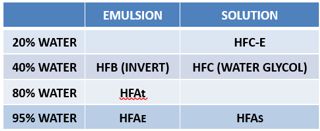

Water offers maximum fire resistance but brings with it issues of low viscosity and lubricity, temperature limitations and support for microbial growth. Fire resistant fluids have evolved based on differing levels of water and technical approaches, hence the following main fluid types exist, as per ISO 6743:

Note: HFA fluids are usually supplied as a dilutable concentrate whereas other types are ready to use.

Note: HFA fluids are usually supplied as a dilutable concentrate whereas other types are ready to use.

Each type attempts in different ways to capitalise on the benefits of water and offset its limitations. Houghton are at the forefront of developing thickened HFA fluids with 80% water, (HFA-T) and high performance water glycols with only 20% water (HFC-E). Though not yet classified officially by ISO6743-4, both types are designed to balance the conflicting requirements for high fire resistance and good lubrication and are gaining popularity from users.

All fire resistant fluids offer better fire protection than oil, but there is no 'fire-proof' nor 'universal' fluid, so selection depends upon achieving a suitable balance between risk, overall system/fluid/maintenance cost and other factors, such as impacts on process and environment. The table compares the key features of each fluid type.