Self-study lesson plans and training record download page.

All designs have different duty requirements

The design and operation of every piece of hydraulic equipment will be different. Some machines are designed for only 250 hours of intermittent, full load working and some for 10000 hours of continuous, full load operation. The components used, circuit designs, and maintenance procedures will be different for each system, depending on its needs. It is therefore important that users do not operate equipment designed for intermittent use, continuously, for example.

Production vs development designs

The risk of failure or accident will always be much higher with new, development or custom machines, than on fully proven production machines. It is important to understand what type of equipment you are working on and take extra precautions if there is no long history of a design working safely. Development environments normally have far more restrictions for public access and often the operators are fully protected from the hydraulic equipment as it will be located inside a sealed test cell. When buying equipment it is vital to know whether it is fitted with appropriate guarding or requires additional operator protection screens.

Risk assessments and training

Make sure that someone has completed a proper risk assessment and that the assessment gets reviewed every time any changes occur.

Make sure that all operators and maintenance staff have been appropriately trained for the equipment being used.

See our safety training modules here

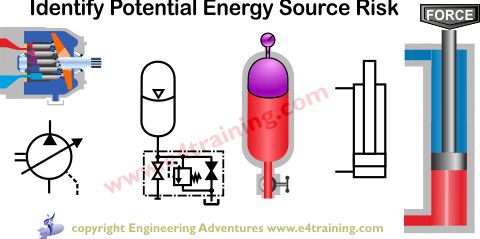

Be aware of the potential risks

Hydraulic accumulators retain energy even when the power is turned off. Unsupported cylinders retain potential energy and must be lowered safely to mechanical stops. Small temperature changes will generate high pressures in sealed volumes.

Make sure you complete the full safety and potential risks training sections to understand these issues. Check the equipment you are using to see which components or features it contains and where any risk points may be.

Beware irregular procedures

Studies have shown that 60-70 % of injuries occur from irregular procedures are carried out. This may be, for example, when the equipment is not being used in the correct way, perhaps because a small fault has occurred somewhere and a physical or procedural change has been implemented to work around this. It could be worthwhile remembering this and always taking extra precautions when working in unusual environments etc.

Hydraulic hose failures

Hydraulic hoses require periodic replacement and must be correctly installed and regularly inspected for wear or damage. Make sure that someone is responsible for checking each hose and that they are completing this work effectively. But even if they are, it is always recommended that the operator checks the hoses and equipment every time the machine is started always keep an eye out for unexpected damage or wear.

Make sure that all operators and other personnel are adequately protected against the risk of flying ends and oil injection injuries.

Maintain fluid cleanliness at all times

Over 80% of failures are caused by fluid contamination. Dirt can enter the fluid from the atmosphere via the air breather or cylinder rods etc. Poor housekeeping and dirty environments will increase the risk of contamination getting into the fluid so it is vital that operators maintain the cleanest local environment possible.

Dirt is also generated by components when they are operated unusually harshly or outside of their normal working conditions. Take care with how you operate equipment and it should last much longer between failures.

Performance and calibration limits

Users must understand the performance limits and normal operating conditions for the equipment. Working outside the specified temperatures or pressures will result in a difference in how the machines work. Prolonged operation outside the standard limits is likely to result in early failure of the equipment.

Modern instrumentation and sensors are likely to have specific dates when they need to be recalibrated. Failure to check and recalibrate these devices may result in the system running outside of its normal design limits and therefore dangerous failures of breakdowns occurring.

Environmental protection

Make sure that in the event of a breakage or failure, NO fluid leak will be able to escape into the environment. It is always important, and in most countries, a legal requirement to protect the environment.

A common solution is to build a bund wall around the power unit or hydraulic system. Then if any connection or pipework leaks the complete reservoir volume can be retained with the bund wall.

Tank failures do happen but the most likely cause will be a slow leak or syphon point that occurs overnight or at a weekend when no one notices. If the fluid cannot be contained and a leak would be detrimental to the environment, then bio-degradable fluids should be considered.

Typical start-up procedure

See our maintenance section for a typical start-up, operating, and shut-down procecure.