Refresh hydraulic actuator basics first

- What hydraulic cylinders are used for

- How hydraulic actuators work

- Different types of hydraulic cylinders

Tips for operating and maintaining hydraulic cylinders

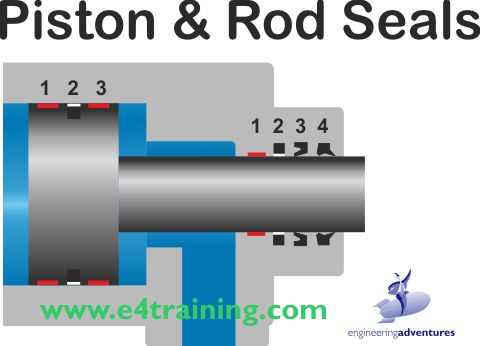

Piston seals are one of the most critical areas in every hydraulic circuit. If rod seals start to fail then contamination will enter the system and gradually damage ever pump and valves it reaches. Always store cylinders with the rods retracted, and not exposed to the atmosphere, whenever possible. If they must be left extended, for a lock gate perhaps, then exercise the cylinders, perhaps every month, to ensure the rod is coated with fluid, to help protect against corrosion.

Rod seals play the vital role of limiting the amount of contamination that enters the fluid. The scraper or wiper seal is designed to clean the rod as it retracts into the cylinder. There are one or possibly two main seals that prevent the fluid from leaving the cylinder. The first can be energised by the cylinder pressure although the second must be self-energised by a spring. Seals must always have some lubrication so two seals is the limit although issues can occur if the second seal is running too dry. Often guide rings are also used to prevent side loads on the cylinders creating metal to metal contact, which again would lead to contamination and reduced reliability of other components.

For storage or transportation, it is recommended to part fill (75%) each cylinder with preservative fluids. These fluids have vapour phase inhibitors to stop the areas inside the cylinder that are not in contact with the fluid from rusting. You must NEVER full fill a cylinder and block the ports as thermal pressure changes are likely to exceed the maximum rating of the cylinder and cause it to fail.

How to specify hydraulic cylinders

Cylinders will be sized against the load they will see and safety factors added. The cylinder pressure required may dictate which type of cylinder is used although more likely is that the application dictates the type of cylinder and the pressure available to set the minimum size.

Check for pressure intensification on the annulus side and select your cylinder pressure rating on this higher figure, rather than the maximum pump supply pressure.

Rod buckling limits must be checked against the mounting style selected. This will determine the maximum stroke possible with the cylinder rod size selected. There are maximum stroke tables or graphs in most cylinder datasheets similar to page 204 here.

Check that the cylinder style you have selected is appropriate for the shock loads and duty you expect. Remember annulus intensification can exceed the maximum working pressure.

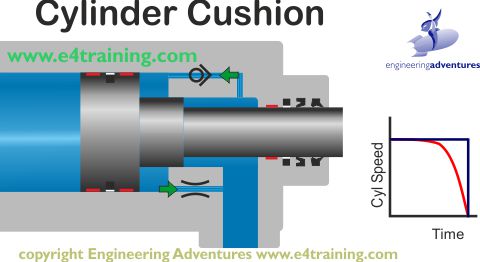

Consider your application to decide whether cushions bleed nipples are required. Also, consider the appropriate rod finish and cylinder body paint finish. It may be that additional protection is required for marine environments etc. and there are several different rod materials or coverings that available.

If you are having issues with seal life or have a special machine that requires particular attention then we recommend you talk directly to the cylinder suppliers as there are many different seal types available for custom cylinder applications.

Consider whether cylinder position feedback is required and whether this could be better accomplished with position monitoring built into the cylinder rod.

Design Tips, techniques, and potential issues

Typical cylinder speeds tend to be around 50 to 100 mm/sec with 200mm/sec as a maximum for normal cylinders. Servo cylinders can achieve a maximum of 500 mm/sec but only by using special seals etc.

If harsh operation is likely to be a problem then cushions are recommended from as low as 20mm/sec.

See the manufacturer's datasheets to check buckling limits.

Hydraulic cylinders are sealed using a combination of specialized seals. Hydraulic Rod seals prevent leakage of fluid from within the cylinder to the outside while hydraulic piston seals prevent fluid from flowing across the cylinder head. This allows pressure build-up on one side of the piston, making the cylinder extend or retract. Wear rings guide the piston and piston rod within the hydraulic cylinder, absorbing transverse forces, preventing metal-to-metal contact. Scrapers or Wipers scrape dirt, foreign particles, chips or moisture from the piston rods as they retract into the cylinder, preventing contamination.

If you are working in harsh environments then consider what different rod materials and/or coating may provide extended life. Modern coatings can significantly extend the life of a cylinder in certain environments.