Self-study lesson plans and training record download page.

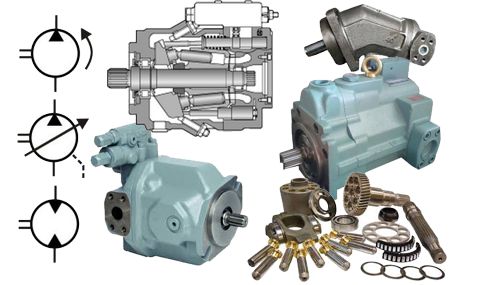

What function hydraulic pumps and motors perform

Hydraulic pumps provide a flow of fluid into a system based on their capacity or displacement.

How hydraulic pumps and motors work

All pumps work by transferring rotary power into an area of changing volume. As the volume increases, atmospheric pressure acting on top of the fluid in the reservoir pushes the fluid into the new space. The pump should not suck the fluid as this is likely to result in damaging cavitation or aeration. Once the full volume has been reached then timing grooves or ports of the pump, open to allow an area of decreasing volume to push the fluid out into the hydraulic system. The system will set the pressure by the load, not the pump, but each pump type will be capable of operating at a different maximum pressure.

The pump flow is not constant but includes small pulsations or noise harmonic, based on the number of gears or pistons.

Hydraulic motors work in the reverse direction to pumps e.g. pressurised fluid acts against the motor pistons or gears and drives the shaft rotation. Often pumps and motors use identical parts except for the timing slots / port plates and additional case drain line. The case drain line is required to stop high internal pressure exceeding the limit of the shaft seal. In practice some designs are more suited to pumps and others more suited to motors.

Understand hydraulic pumps displacement

Fixed or variable displacements are measured in cubic centimetres per revolution, cc/rev or cubic inches per revolution, cuin/rev. For example a 10cc/rev pump will give 10 Litres per minute (L/min) at 1000 revs/minute.

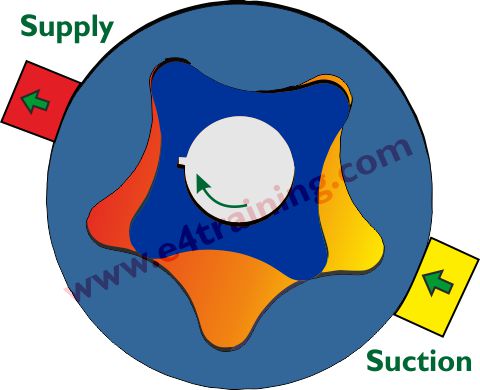

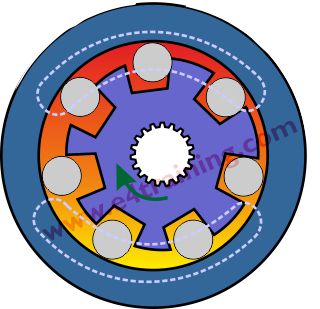

Gerotor and geroler pumps and motors

Gerotor pumps and motors come with a range of impeller designs e.g. two or multi-lobe versions, depending on application requirements.

They are typically used for lubrication and boost pump or light duty motors. More commonly found in low-pressure automotive systems.

Another variation on the gerotor design is the higher performance geroler design of pump and motor. They are typically used for low-cost, low pressure, light to medium duty drive systems. Again more commonly found in automotive and lightweight mobile applications

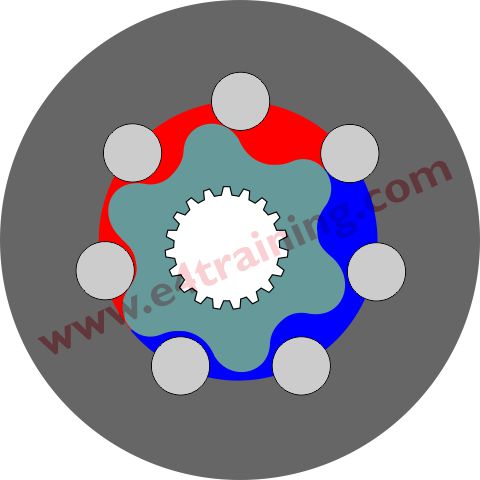

External gear pumps and motors

External gear pumps come with fixed or floating bearing designs. Several different types of low noise versions are also available. External gear motors are available but not as widely used as gear pumps. They are all fixed displacement only.

They are typically used as robust, lower-cost pumps and some motors. Widely used in low to medium duty mobile systems or lower-cost industrial power units.

Internal gear pumps

Internal gear pumps and motors are available from several manufacturers with different design details and numbers of teeth. Fixed displacement only and a more limited size range than external gear pumps. They also cost significantly more.

They are typically used in medium-cost systems where robust, low noise is required. Typically industrial power unit pumps, but not motors.

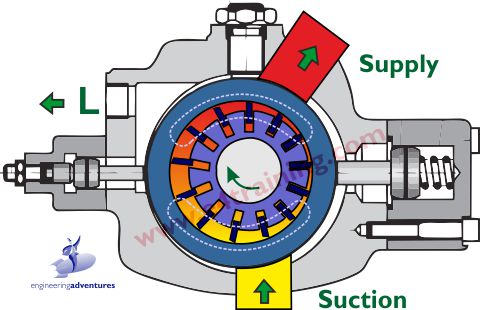

Vane pumps and motors

Vane pumps come in twin chamber, fixed displacement only, or single chamber, fixed or variable displacement. Design quality can vary, along with the pressure rating, duty, and noise. Roller vane pumps are version used in the automotive sector for relatively low cost, robust operation, but not particularly high performance. Vane motors are available but not widely used.

Vane pumps are typically used in industrial, medium cost power units. Where low noise is required but also relatively low pressures and duty are required. Vane motors are available but not widely used.

Roller vane pumps are typically used in low to medium performance applications but mostly in automotive applications.

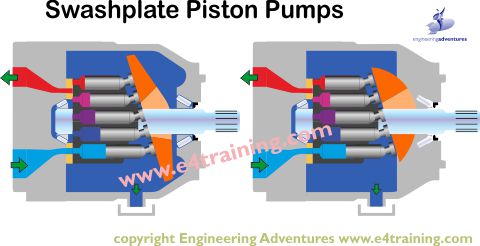

Axial piston pumps and motors

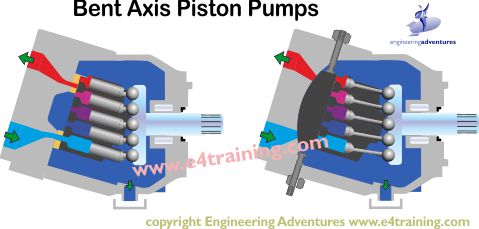

Axial piston pumps are available in fixed and variable displacement models. They also both come in swashplate or bent axis designs. All piston pumps require an external case drain line as well as the inlet and outlet flow connections.

There are many different design variations and build standards available from a large number of manufacturers. Subtle differences in design will make one type of pump more suited to a particular application than others. In general, a higher price reflects a higher duty or life expectancy, but the huge volumes produced for the mobile market have shaped the types of pump that are commonly available.

Piston pumps also come with a wide range of controllers that allow them to provide a wide range of different functions or performances that are required for different applications.

Although there are many exceptions, piston pumps tend to be swashplate designs and piston motors are bent axis designs. Both formats are available fixed and variable designs.

Axial piston pumps and motors are typically used in medium to high pressure, heavy-duty applications. Typically excavator lifting or drive systems plus continuous duty industrial power units.

Radial piston pumps and motors

Radial piston pumps are available in a number of different design formats from different manufacturers and with different numbers of pistons within each design.

Radial piston pumps are typically used in very high-pressure industrial applications such as industrial presses, test rigs, etc.. They are generally more expensive but can deliver higher pressures Radial piston motors are far more common than radial piston pumps because they are widely used as mobile equipment wheel motors. These also have the ability to switch pistons ON or OFF to change displacements and therefore drive speeds. They are used across a wide range of medium to high duty mobile equipment wheel drives.

How to specify hydraulic pumps and motors

With so many different manufacturers and products, we cannot provide specific performance details or recommendations. Instead, we will highlight the important factors in each particular design type, but users must check the manufacturer's datasheet to compare how well different products perform.

Some of the important areas to consider with pumps and motors are:

1. Cleanliness limits e.g. the level it needs from the system to work reliably and the best it will allow the system to run at, considering the duty at which it will work. Users should also consider what the consequences will be if the pump was to fail e.g. what would be the nature of the debris released during a typical failure. Does filtration need to be improved?

2. What is the minimum suction head requirement? Can pump suction conditions be improved, particularly when starting from cold? Will units operate at altitude which could increase potential issues.

3. What is the predicted life of the pump under the expected duty cycle? Remember that rated life predictions are based on normal operating conditions, which will not be the same for all installations. Have peak pressure or continuous pressure ratings been used?

4. Consider what effect the system dynamics will have on pump life e.g. a high frequency of pressure changes or very steep pressure rise rates.

5. Does the drive system apply acceptable side loading to the pump drive shaft?

6. Is the pump, its seals and operating fluid appropriate for the working temperature range.

7. Is planned maintenance appropriate e.g. is the fluid health checked or could it be damaged by aging or local operating conditions, therefore, reducing the life of the pump? Can the temperature of the case leakage line be monitored as a way of predicting pump damage?

8. Could volumetric efficiency drop at particular working speeds, temperatures, or pressures? Is there enough installed power to operate under the worst conditions or are certain environmental operating limits required.

9. Could overall efficiency drop at particular speeds or pressures?

10. Does the pump require a separate case leakage line? And if so what is the maximum pressure permitted. It's always recommended to have a motor case leakage line even it the pump version doesn't. Motor return lines are likely to exceed shaft seal limits and therefore without a drain line, high case pressures will cause seal failures or reduced life.

11. Will pump generated noise be an issue? Are quieter pump options available or can the noise propagation throughout the system be contained instead?

12. Has the installation been considered? Are lifting points or special tools required.