Added security features

Operator safety must be the top priority in any hydraulic system, particularly where load control is required.

Sun's cartridge valves include several unique features that provide added security for protecting your equipment from failure.

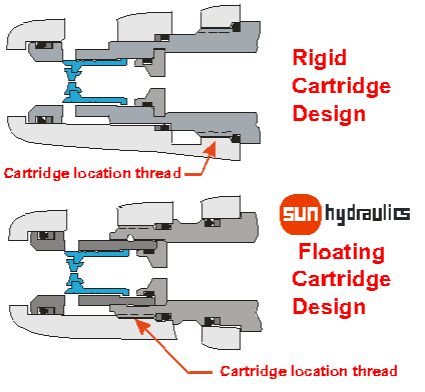

Floating cartridges are less likely stick when distorted

Operate the slidebar and compare the superior performance of the Sun Hydraulics floating cartridge design with that of other cartridge designs.

Floating cartridge description

It is never possible to maintain perfect concentricity between a thread and a bore. The resulting misalignment can cause side loads that will distort the cartridge body. This can have a significant effect on the spool clearance and may result in intermittent or unacceptable performance. Changes in the valve's internal leakage will also affect its contamination resistance and could therefore result in early valve failure.

A significant benefit of the Sun Hydraulics, cartridge system is the ability of the honed spool section to float relative to the cartridge's thread. This floating design will compensate for misalignments in the cavity.

This security also allows tighter machining tolerances to be maintained and therefore more reliable and better performing valves.

Floating cartridge explained

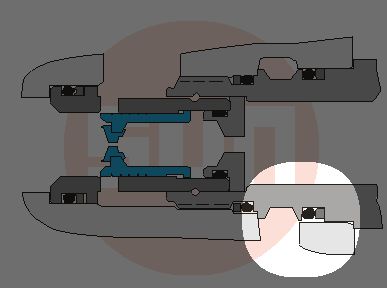

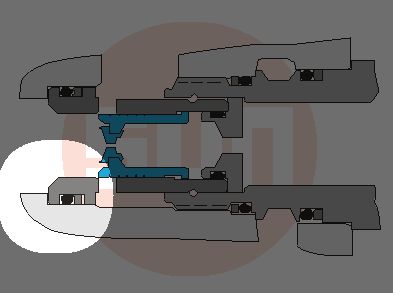

The shoulder diameter under the hexagon provides a guide to help ensure the cartridge is centred in the cavity.

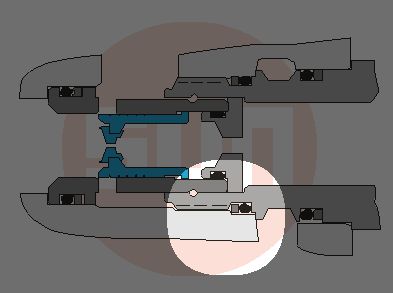

Higher installation torque

The flat shoulder provides a stop which supports the load generated by the thread without inducing radial load. Along with the floating cartridge design this allows a much higher installation torque before distortion or misalignment

Avoiding spool bore distortion

For a given thread size the central thread position results in maximum flow capacity, minimises the effect of eccentricity, and distributes the thread loads deep in the manifold.

Easy assembly

The stop in the bottom of the cavity supports the free floating subassembly during operation; retaining wire is used only during assembly.