1-2 What counterbalance valves are used for.

Counterbalance valves are also known as load control and over-centre valves.

Their most common use is for supporting loads in lifting applications such as cranes, scissor lifts or excavators. They ensure the loads do not drop when the power is turned off. They also control the load lowering to make sure it is safe and stable.

Their most common use is for supporting loads in lifting applications such as cranes, scissor lifts or excavators. They ensure the loads do not drop when the power is turned off. They also control the load lowering to make sure it is safe and stable.

When machine loads change direction or go over-centre then counterbalance valves compensate for the effect of load pressure change on flow through the restricting orifice, this helps to control the load and therefore allows the system to work at a more consistent speed.

When machine loads change direction or go over-centre then counterbalance valves compensate for the effect of load pressure change on flow through the restricting orifice, this helps to control the load and therefore allows the system to work at a more consistent speed.

1-2 How counterbalance, load control valves work

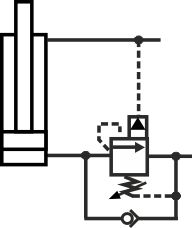

A simple way to think of a load control valve is as a pilot operated relief valves mounted on the cylinder port. With no pilot pressure, the cylinder will only move when the pressure exceeds the relief valve setting. When pilot pressure is applied, the pressure at which the relief valve opens is lowered to one that allows safe control.

The term 'pilot pressure ratio' is used to describe the internal area ratio of the valve. Different area ratio valves are used to provide more stability or efficient operation in different machine designs.

A check valve is used to allow fluid to flow back through the counterbalance valve without restriction. This allows the load to be raised with minimal pressure loss through the valve.

In reality, counterbalance valves form their own complex, closed-loop control systems. This means they can be difficult to set up and suffer instabilities under some operating conditions.

2 Different types of counterbalance valve

The vast majority of counterbalance valves are used as cylinder or motor, load control systems. They tend to be mounted directly onto the actuators and therefore tend to be cartridge designs for insertion into the actuator mounted manifolds.

The valves themselves come in a wide range of different options and versions. Pilot ratios, response restrictions and pilot line connections are the main variations. Although there can be significant performance variations between manufacturers.

3 Tips for operating and maintaining (See Pro course)

Load holding applications are covered by the LOLER regulations whereby every new build or repair needs to be checked that the load does not fall more than a set amount of a given period.

3-4 Typical operating characteristic(See Pro course)

TBC

4 How to specify counterbalance or load control valves (See Pro course)

TBC

4 Design Tips, techniques and potential issues (See Pro course)

There are several tips for selecting counterbalance valves in other sections of this site but it can be a case of discussing your application with the valve manufacturer's engineers and perhaps trying different valves in the actual equipment to see which one works best.

Try the counterbalance valve pilot cracking pressure calculation