Hydraulic design priorities

Learn which type of hydraulic valves you require

Different designs for different markets

Hydraulic equipment suppliers generally offer different products for different markets, based on their experience of what works. For example, mobile pumps and valves are different to industrial pumps and valves. Marine and machine tools etc may also have different versions of similar valves but modified to suit their own working environments.

The following slides provide some rough guides for the design priorities in each market. You may need to make sure that the components you specify are appropriate for your application but you must always remember to consider that the advice given on this website may only apply to the one application being discussed, rather than all of them.

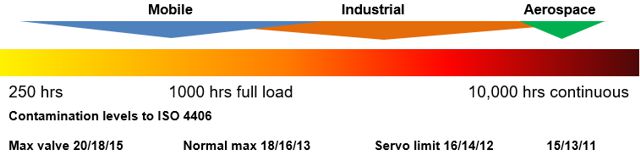

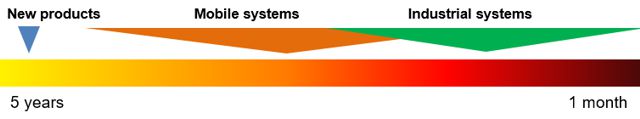

Reliability and Duty

The design life or duty of a hydraulic system can vary greatly. 90% of all hydraulic failures are due to contamination so designing a system that starts and remains clean is vital.

Mobile applications can be simple and robust but sometimes lower cost and therefore quality.

Mobile applications can be simple and robust but sometimes lower cost and therefore quality.

Industrial systems may be better quality for longer life but can be more complicated and therefore less reliable in more arduous environments.

Industrial systems may be better quality for longer life but can be more complicated and therefore less reliable in more arduous environments.

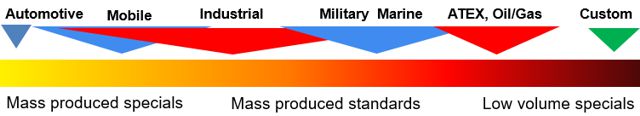

Hydraulic system costs

Hydraulic system costs will vary significantly. Probably the most important factors are production volume, environment, life cycle duty, market and quality of control.

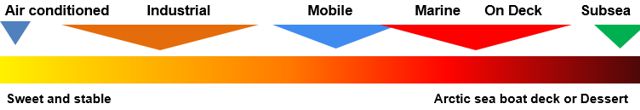

Hydraulic environments

The external environmental conditions around equipment will have a major impact on the component design.  Industrial applications are generally dry and reasonably clean, while

Industrial applications are generally dry and reasonably clean, while  mobile hydraulics will normally get very wet and muddy. Marine application with salt water and extreme temperatures are some of the most arduous.

mobile hydraulics will normally get very wet and muddy. Marine application with salt water and extreme temperatures are some of the most arduous.

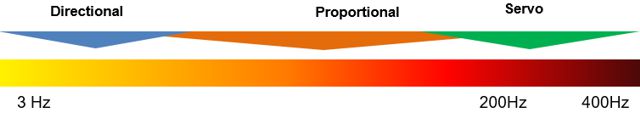

Quality of control

Many applications just need to move actuators with directional valves that are either open or shut.

Proportional valves allow actuators to be accelerated more smoothly or driven at a controlled speed.

High performance proportional and servo valves can provide a much faster response with better resolution and less hysteresis etc.

With any type of control, the system's natural frequency will need to be compatible with the valves selected.

Development time, Design risk

Industrial design techniques offer reliable 'right first-time' design.

Mobile design is generally closer to the maximum limits of the equipment and the wider operating ranges need field development trials to make sure the design is right.

Hydraulic leakage

There are two main groups of hydraulic valve design. Poppet valves tend to have very low leakage usually only measured as visible drops per minute or cylinder movement per hour. Spool valves will always have some clearance between the spool and body and this will always result in a leakage in the order of 30 cc/min, although this will depend on fluid temperature and pressure.

Maintainability

Initial cost can be kept low by making systems that just do one job and don't include additional features to make servicing and repair much easier.

Through life running costs can be reduced with more robust valves or increasing equipment availability with easy to install spares.

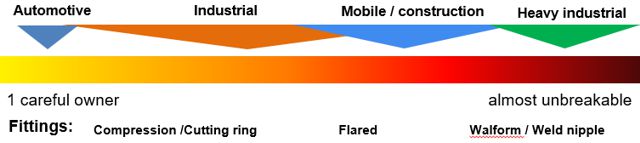

Ruggedness

The life and reliability of hydraulic equipment will be affected by the level of vibration, internal loadings, single shock events etc.

How much abuse it has to withstand from the operator is also important.

Another key factor is the type of hydraulic fittings used and how well they can withstand abuse.