Understand pressure reducing valve design features, specification and performance limits.

Self-study lesson plans and training record download page.

3 Tips for operating and maintaining

Make sure all of the air is vented from the circuit before the valves are set. Any air remaining in the system, perhaps even trapped in manifold galley-ways, can make the system spongy and result in oscillations or vibration.

Reducing valves may be set to zero pressure when the equipment is delivered. This is to make the equipment safe for commissioning but does mean they need to be reset before use.

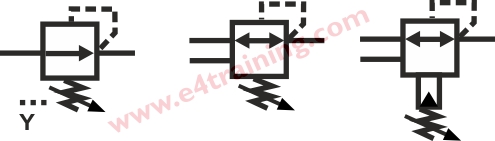

Watch out for the effects of high pilot flow rates. Some reducing valves require leakage flows to keep them stable and when used in pilot lines, which may expect low flows, these flows and resulting pressure drops may be significant enough to affect other valve settings. Also, pay attention to the maximum relieving flow rates. The third, drain line may be connected to a pilot drain system on the assumption it will only see small leakage flows, however, if the system relieves large flows into this line then it could upset several other connected valves. The valve symbol should show if the drain line is connected as a pilot line to the spring or as a third flow line to the valve body, but not all schematics have always used these latest drawing standards.

3-4 Design features and operating characteristics

Although there are not as many options with reducing valves as with relief valves, many of the design features and operating characteristics the same causes and implications. These have already been covered in the relief valve training section so will not be covered again here.

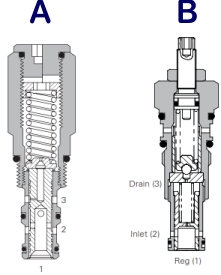

The image shows a section through a direct operated valve A and pilot operated valve B.

3-4 How to specify pressure reducing valves

As with most hydraulic valves, the first thing to consider is your industry and environmental requirements. It's generally very clear whether you are working in a mobile or industrial situation but every application will have its own priorities for cost, duty, environment, ease of maintenance and quality of characteristics etc. It's likely this will be the main driver in your component selection and we will cover these option in more detail in our strategies and project management sections.

Once the type of valve has been decided it's time to look at the detail.

Consider whether a relieving function will be required for the load. Perhaps the actuator could be driven backwards by the load normal operation, or in event of operator error. If this can never happen then a reducing only valve could be used but if you need a reducing/relieving valve then make sure backflow capacity is adequately sized.

Next, consider the pressure and flow range you will require.

Look at the supplier's datasheet to find the most appropriate working range. As a general rule the more expensive, larger valves will give better performance e.g. flatter characteristics. If this is not clear from the datasheet characteristics then look at the design of the valve. You can often see when there has been more attention, and probably testing, paid to the design detail. Although the finer design detail can also be a sign of a valve that will be more sensitive to contamination. See our contamination resistant design section to understand this further.

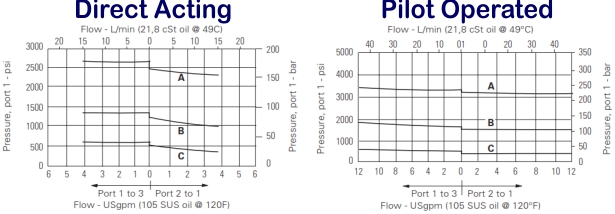

If you require a fast response then select a direct-operated version which is more dynamic and has less internal leakage. The pilot operated versions tend to be more stable and give better characteristics over a higher flow range, but are slower and have increased leakage.

The quality of control and operating environment will probably dictate which design you choose.

4 Design tips, techniques and potential issues

Make sure you have good clearance between the reduced pressure and any relief valve reset pressures. Don't forget that when valves are open and relieving, you may have significant pressure drops in pipework and fittings between different valves.