Understand where and why check valves are used. The different types available and how they work.

Self-study lesson plans and training record download page.

1-2 What check valves are used for

Check valves are used for a wide range of different functions. The type of check valve will vary with different equipment and flow rates. The name can also change as they may be known as anti-siphon, non-return, bypass, load holding, PO check, one-way plus a few others.

Check valve functions include:

Only allowing flow in one direction.

Different spring rates limit or maintain a pressure upstream of the valve.

Check valve uses include:

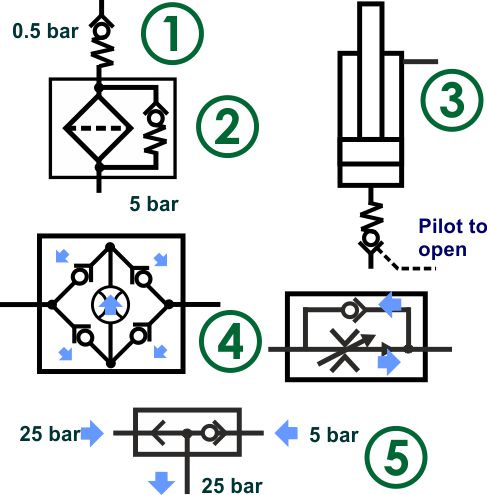

Item 1 prevents backflow which would cause the dirt collected by the filter re-entering the circuit. It will also work as an anti-syphon valves. These are placed in return lines to stop fluid draining out of the reservoir when valves are removed for maintenance.

Check valves with springs, item 2, can be used as simple, low-pressure relief valves although they don't have a good pressure rise rate characteristic. This application shows a filter bypass valve. They can also be used to maintain slight back-pressure on systems if required for control purposes.

Item 3 shows a PO check valve. These are commonly used for load holding e.g. locking a cylinder in position so that it does not move once the directional control valve or supply pressure has been switched off. Check out our 'understanding load control' course or circuit simulation to learn more.

Item 4 shows how check valves are used with flow control devices. The first application is a ensures that flow only ever passes through the flow meter in one direction and the second example we get full flow in one direction and controlled flow in the other.

Shuttle valves, Item 5, always feed the highest pressure back into the third line and are common in load sensing, pilot line feeds or pressure switching circuits.

Check valves can be used to provide a range of sequencing or safety functions. Four PO check valves can be used as a directional valves when very low leakage or very high flows are required. However, in these applications, they are normally called logic valves. More details on this are provided in our logic valve training module.

In summary:

Preventing backflow or anti-siphon.

Low-pressure relief or filter bypass.

Holding loads with minimal leakage.

Pilot pressure feeds, sequencing or switching.

1-2 How check valves work

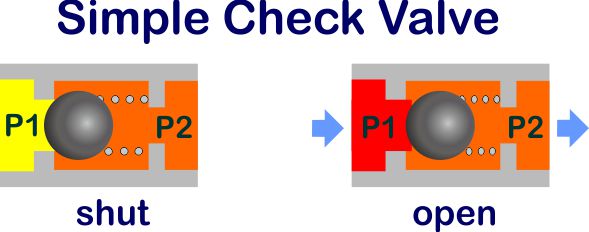

Check valves only allow fluid to flow in one direction.

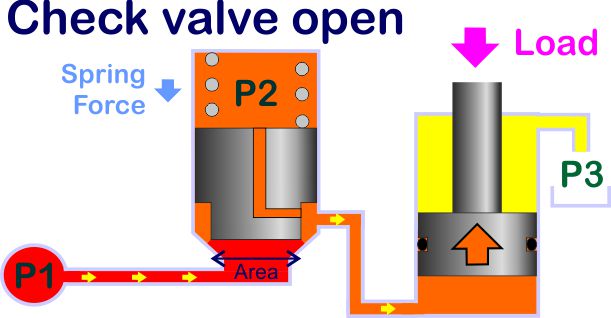

When pressure is higher on the ball side it pushes the ball or poppet against the spring and opens a path for the fluid to pass.

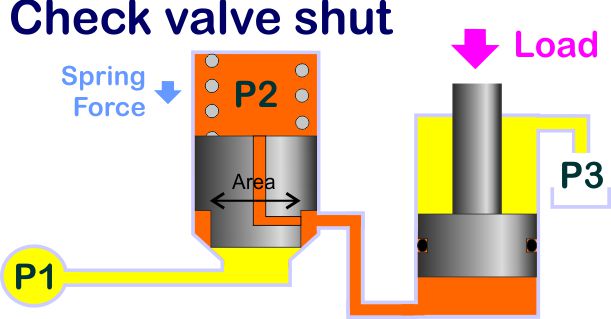

When pressure is higher on the spring side the ball or poppet closes against the seat and flow stops.

The spring force determines the pressure difference at which the valves start to open.

There should be virtually leak-free sealing of flow in the other direction.

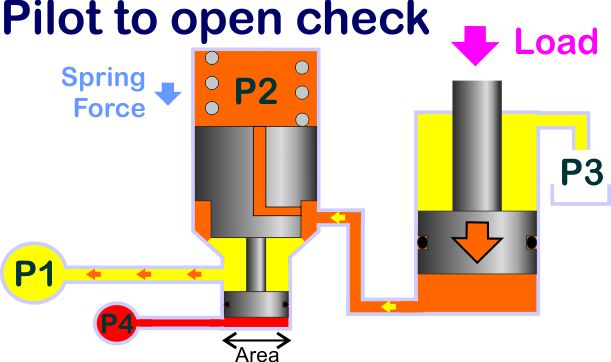

Pilot operated check valves (PO checks) have the facility whereby an external pressure can be used to open the valve to allow flow in either direction.

Look at the different check valve symbols here.

1-2 How shuttle valves work

Shuttle valves have two seats and three connecting lines. They always feed the highest pressure from either of two supply lines, back into the T line. Shuttle valves may be used within a daisy chain of valves to feed the highest of many lines back into one.

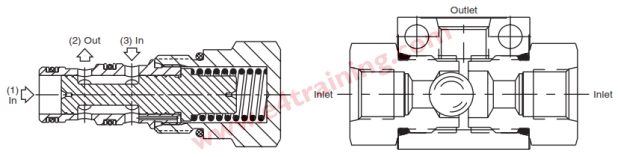

Shuttle valves are commonly used as cartridge inserts or line-mounted valves. They can, however, be very difficult to spot as they can be hidden inside manifolds or look just like line mounted fittings.

Higher pressure at P1

Higher pressure at P2

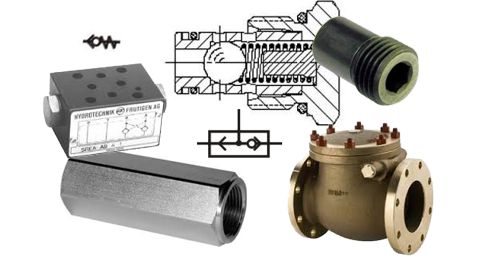

2-3 Different types of check valve

Check valves are sometimes also known as non-return, one way, anti-siphon, bypass relief valve, backflow prevention and flap valve.

Check valves can be purchased with a range of spring settings. These are usually very low, typically 0.5 to 1.0 bar, but also around 5 bar is common for bypass relief valves. They are rarely above 10 bar.

Check valves can be purchased with a wide range of flow sizes from just a few L/min to several hundred L/min.

Check valves without springs provide less resistance and therefore pressure loss.

Pilot-to-open (often called pilot operated) check valves allow flow in both directions, e.g. backward through the valve when a pressure is applied to the pilot line.

Pilot-to-close check valves will not open in either direction when pressure is applied to the pilot.

Reverse direction check valves are generally used to make the manifold design more compact e.g. with flow from port 2 to 1 rather than port 1 to 2

Other types of check valves include mechanically operated or vented.

Check valves come in a wide range of formats and installation styles. These include line mounted, cartridge, CETOP mounted, sandwich plate and flange inserts.

Advanced check valve training

Learn more about check control valves in our 'Professional Training Section'. Understand their design features, performance limits, and how to specify check valves.