Self-study lesson plans and training record download page.

Hydraulic pipework sizing utility

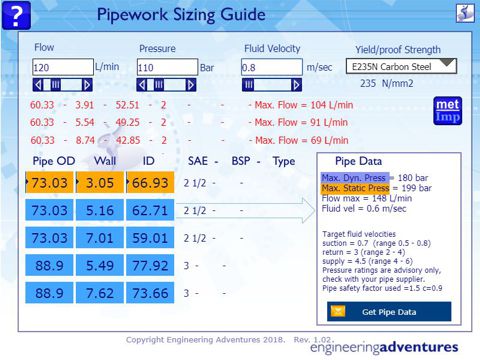

This module explains the how to size hydraulic pipework using the e4training.com design guide. It clarifies the parameters you need to enter into the software and explains the basis and significance of the results.

While this simulation does provide some intelligence and sizing routines it does not have an unlimited database of all pipework that is manufactured. Users must check the data against their own pipework suppliers to validate the results shown

Enter The Hydraulic Conditions

To use the pipework sizing guide you will need to enter the correct data for each pipe e.g. all supply, return and drain pipes etc.

Enter the maximum flow in L/min that will pass through the pipe. Select the met/imp button to see the imperial equivalent of this value.

Enter the maximum hydraulic working pressure that will be seen within the pipework. This value must reflect any intensified local pressures such as those from cylinder annulus intensification etc. However, this value does not need to include any 1.5 times pressure test value. The calculation includes a 1.5 safety margin which is designed to cover the usual 1.5x pressure test during final test or commissioning.

Enter the maximum permissible fluid velocity. These will be different for the supply, return and suction lines and are likely to be within the following ranges.

suction = 0.7 (range 0.5 - 0.8) m/sec

return = 3 (range 2 - 4) m/sec

supply = 4.5 (range 4 - 6) m/sec

The pipe material can be selected from the drop-down list box. This sets the yield or proof stress for that material. The results contain a range of standard pipe sizes that are available in E235N carbon steel although users must be aware that not all sizes may be available in stainless or other steel options.

Understanding the Results

Once users have entered their data the pipework sizing guide will automatically select suitable pipework from the standard range available. The results are based on ensuring the inside diameter is sufficient to keep the fluid velocity below the level set by the user. The program also checks that the predicted pipe pressure rating is above that of the working pressure.

The pipework pressure ratings are advisory only. The actual pressure rating will depend on the supplier recommendations for the pipe used, corrosion allowance and assembly method e.g., welded fittings or type of bends etc. Always check the values specified by your hydraulic pipe supplier. The calculations do make an allowance for pressure testing at 1.5 times the maximum working pressure.

The program suggests two levels for pressure rating compliance. The blue coloured pipework sizes should be capable of operating under full dynamic pressure conditions; which is how most fluid power hydraulic systems operate. The orange coloured pipework may be used with caution, in some static applications. Always check the values specified by your hydraulic pipe supplier.

Selecting the pipework sizes on the left-hand side presents more information about that pipe within the highlight box on the right. The arrow indicates which size this data relates to.

Above the suggested pipework are some additional pipework options, shown in red. These lie above the required fluid velocity limits but may be useful to know if final feeds and speeds have not been set.

Export the Result to a Spreadsheet

Once you have decided on the most appropriate design you can export the results to Excel or any other spreadsheet. Use the 'Get Pipe Data' to go to the results page. On the registered version you can copy or email the data to your PC. With the unregistered version, the data will be emailed to yourself and a potential supplier in your area.

Next Open Excel. Paste your comma-separated values into the document, column 1.

Select column 1 and open the 'DATA' tab.

Click on the 'Text to Columns' button and follow the wizard (delimited-comma).

You will then have an excel table you can manipulate as required.

Make sure you check the results with your own calculations in Excel or Mathcad etc.